Page 30 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 30

Overview 9

Desiccant

system

Exhaust

Absorption

Steam or chillers Dehumidification

hot water

Air handler

Steam

turbine

generator

Heat

recovery

unit Process

loads

Electric

chillers Cooling/heating

Engine/

Fuel Generator Electricity

turbine

Building or facility

Fuel cell

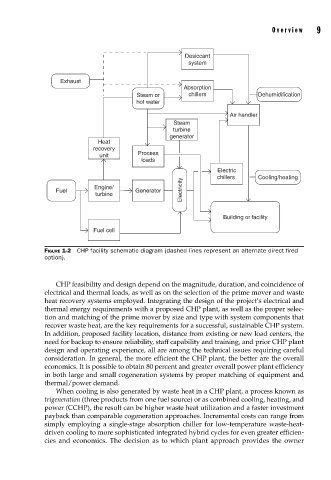

FIGURE 1-2 CHP facility schematic diagram (dashed lines represent an alternate direct fi red

option).

CHP feasibility and design depend on the magnitude, duration, and coincidence of

electrical and thermal loads, as well as on the selection of the prime mover and waste

heat recovery systems employed. Integrating the design of the project’s electrical and

thermal energy requirements with a proposed CHP plant, as well as the proper selec-

tion and matching of the prime mover by size and type with system components that

recover waste heat, are the key requirements for a successful, sustainable CHP system.

In addition, proposed facility location, distance from existing or new load centers, the

need for backup to ensure reliability, staff capability and training, and prior CHP plant

design and operating experience, all are among the technical issues requiring careful

consideration. In general, the more efficient the CHP plant, the better are the overall

economics. It is possible to obtain 80 percent and greater overall power plant efficiency

in both large and small cogeneration systems by proper matching of equipment and

thermal/power demand.

When cooling is also generated by waste heat in a CHP plant, a process known as

trigeneration (three products from one fuel source) or as combined cooling, heating, and

power (CCHP), the result can be higher waste heat utilization and a faster investment

payback than comparable cogeneration approaches. Incremental costs can range from

simply employing a single-stage absorption chiller for low-temperature waste-heat-

driven cooling to more sophisticated integrated hybrid cycles for even greater efficien-

cies and economics. The decision as to which plant approach provides the owner