Page 363 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 363

336 Ca s e S t u d y 2

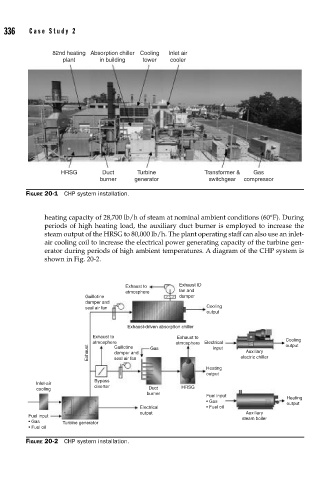

82nd heating Absorption chiller Cooling Inlet air

plant in building tower cooler

HRSG Duct Turbine Transformer & Gas

burner generator switchgear compressor

FIGURE 20-1 CHP system installation.

heating capacity of 28,700 lb/h of steam at nominal ambient conditions (60°F). During

periods of high heating load, the auxiliary duct burner is employed to increase the

steam output of the HRSG to 80,000 lb/h. The plant operating staff can also use an inlet-

air cooling coil to increase the electrical power generating capacity of the turbine gen-

erator during periods of high ambient temperatures. A diagram of the CHP system is

shown in Fig. 20-2.

Exhaust to Exhaust ID

atmosphere fan and

Guillotine damper

damper and

seal air fan Cooling

output

Exhaust-driven absorption chiller

Exhaust to Exhaust to

atmosphere Guillotine atmosphere Electrical Cooling

output

Exhaust damper and Gas input electric chiller

Auxiliary

seal air fan

Heating

output

Bypass

Inlet-air

cooling diverter Duct HRSG

burner

Fuel input

Heating

• Gas output

Electrical • Fuel oil

output Auxiliary

Fuel input

steam boiler

• Gas Turbine generator

• Fuel oil

FIGURE 20-2 CHP system installation.