Page 418 - Sustainable On-Site CHP Systems Design, Construction, and Operations

P. 418

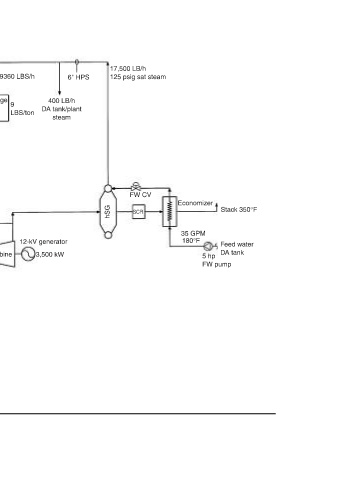

Stack 350°F Feed water DA tank FW pump

Economizer 35 GPM 180°F 5 hp

17,500 LB/h 125 psig sat steam FW CV SCR hSG

6" HPS

400 LB/h DA tank/plant steam 12-kV generator 3,500 kW

0 to 9360 LBS/h 1040 ton 2-stage 9 absorption LBS/ton chiller Cond Turbine

125/15 psig reducing station 149,600 LBM/h 835°F Shaft Combuster 42.7 MMBtu/h 3" NG

HWS HWR Compressor hot water return hot water supply selective catalytic reduction

0 to 16,000 LBS/h Inlet silencer M natural gas outside air

18 MMBtu/h steam to HHW HEX Cond Air filter 480 V ES 160 psig 100-HP NG compressor (type of 3) 1 backup HWR HWS NG OSA SCR

Space heating 59°F DB 56°F WB

40°F CHWS 55 tons Conventional CHP plant.

18 MMBtu/h dump condenser Cond 96°F DB 69°F WB 64°F 3" CHWR 15 psig 750 SCFM 950 Btu/CF COND condensate deaerator exhaust

OSA 147,500 LBM/h NG Legend: DA EXH FIGURE 24-1

390