Page 170 - Synthetic Fuels Handbook

P. 170

156 CHAPTER FIVE

5.5.5 Underground Gasification

The aim of underground (or in situ) gasification of coal is to convert the coal into com-

bustible gases by combustion of a coal seam in the presence of air, oxygen, or oxygen and

steam. Thus, seams that were considered to be inaccessible, unworkable, or uneconomical

to mine could be put to use. In addition, strip mining and the accompanying environment

impacts, the problems of spoil banks, acid mine drainage, and the problems associated with

use of high-ash coal are minimized or even eliminated.

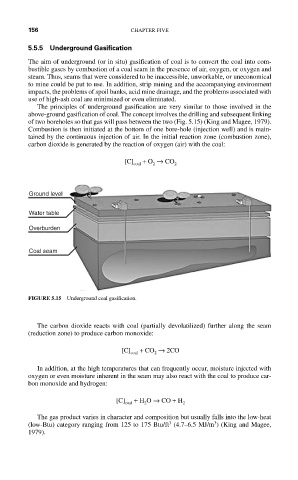

The principles of underground gasification are very similar to those involved in the

above-ground gasification of coal. The concept involves the drilling and subsequent linking

of two boreholes so that gas will pass between the two (Fig. 5.15) (King and Magee, 1979).

Combustion is then initiated at the bottom of one bore-hole (injection well) and is main-

tained by the continuous injection of air. In the initial reaction zone (combustion zone),

carbon dioxide is generated by the reaction of oxygen (air) with the coal:

[C] coal + O → CO 2

2

Ground level

Water table

Overburden

Coal seam

FIGURE 5.15 Underground coal gasification.

The carbon dioxide reacts with coal (partially devolatilized) further along the seam

(reduction zone) to produce carbon monoxide:

[C] coal + CO → 2CO

2

In addition, at the high temperatures that can frequently occur, moisture injected with

oxygen or even moisture inherent in the seam may also react with the coal to produce car-

bon monoxide and hydrogen:

[C] coal + H O → CO + H 2

2

The gas product varies in character and composition but usually falls into the low-heat

3

3

(low-Btu) category ranging from 125 to 175 Btu/ft (4.7–6.5 MJ/m ) (King and Magee,

1979).