Page 172 - Synthetic Fuels Handbook

P. 172

158 CHAPTER FIVE

Oxygen/

Coal steam Iron catalyst

C H FT product

Gasification & H + CO FT x y separation

2

gas cleaning syngas synthesis liquids

& wax & upgrading

Steam Tail gas

Sulfur, Water Ultra-clean

mercury, and liquid fuels

CO , Electric oxygenates & chemical

2

and ash Steam power feedstocks

generation

Electricity

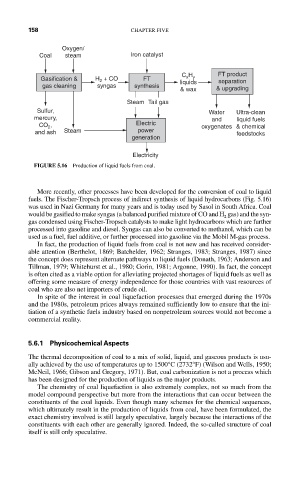

FIGURE 5.16 Production of liquid fuels from coal.

More recently, other processes have been developed for the conversion of coal to liquid

fuels. The Fischer-Tropsch process of indirect synthesis of liquid hydrocarbons (Fig. 5.16)

was used in Nazi Germany for many years and is today used by Sasol in South Africa. Coal

would be gasified to make syngas (a balanced purified mixture of CO and H gas) and the syn-

2

gas condensed using Fischer-Tropsch catalysts to make light hydrocarbons which are further

processed into gasoline and diesel. Syngas can also be converted to methanol, which can be

used as a fuel, fuel additive, or further processed into gasoline via the Mobil M-gas process.

In fact, the production of liquid fuels from coal is not new and has received consider-

able attention (Berthelot, 1869; Batchelder, 1962; Stranges, 1983; Stranges, 1987) since

the concept does represent alternate pathways to liquid fuels (Donath, 1963; Anderson and

Tillman, 1979; Whitehurst et al., 1980; Gorin, 1981; Argonne, 1990). In fact, the concept

is often cited as a viable option for alleviating projected shortages of liquid fuels as well as

offering some measure of energy independence for those countries with vast resources of

coal who are also net importers of crude oil.

In spite of the interest in coal liquefaction processes that emerged during the 1970s

and the 1980s, petroleum prices always remained sufficiently low to ensure that the ini-

tiation of a synthetic fuels industry based on nonpetroleum sources would not become a

commercial reality.

5.6.1 Physicochemical Aspects

The thermal decomposition of coal to a mix of solid, liquid, and gaseous products is usu-

ally achieved by the use of temperatures up to 1500°C (2732°F) (Wilson and Wells, 1950;

McNeil, 1966; Gibson and Gregory, 1971). But, coal carbonization is not a process which

has been designed for the production of liquids as the major products.

The chemistry of coal liquefaction is also extremely complex, not so much from the

model compound perspective but more from the interactions that can occur between the

constituents of the coal liquids. Even though many schemes for the chemical sequences,

which ultimately result in the production of liquids from coal, have been formulated, the

exact chemistry involved is still largely speculative, largely because the interactions of the

constituents with each other are generally ignored. Indeed, the so-called structure of coal

itself is still only speculative.