Page 168 - Synthetic Fuels Handbook

P. 168

154 CHAPTER FIVE

The molten salt system employs a bath of molten salt to convert coal (Cover et al., 1973;

Howard-Smith and Werner, 1976; Koh et al., 1978).

Fixed-Bed Processes

The Lurgi Process. The Lurgi process was developed in Germany before World War II

and is a process that is adequately suited for large-scale commercial production of synthetic

natural (Verma, 1978).

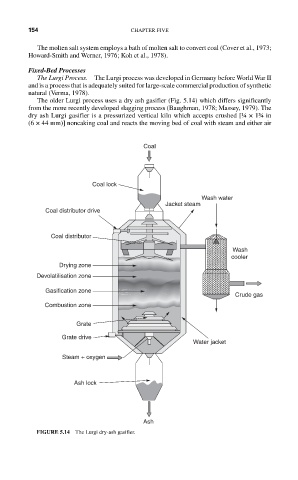

The older Lurgi process uses a dry ash gasifier (Fig. 5.14) which differs significantly

from the more recently developed slagging process (Baughman, 1978; Massey, 1979). The

dry ash Lurgi gasifier is a pressurized vertical kiln which accepts crushed [¼ × 1¾ in

(6 × 44 mm)] noncaking coal and reacts the moving bed of coal with steam and either air

Coal

Coal lock

Wash water

Jacket steam

Coal distributor drive

Coal distributor

Wash

cooler

Drying zone

Devolatilisation zone

Gasification zone

Crude gas

Combustion zone

Grate

Grate drive

Water jacket

Steam + oxygen

Ash lock

Ash

FIGURE 5.14 The Lurgi dry-ash gasifier.