Page 299 - Synthetic Fuels Handbook

P. 299

FUELS FROM CROPS 285

Methanol or ethanol Vegetable oil

Catalyst Transesterification reactor Glycerin

Biodiesel

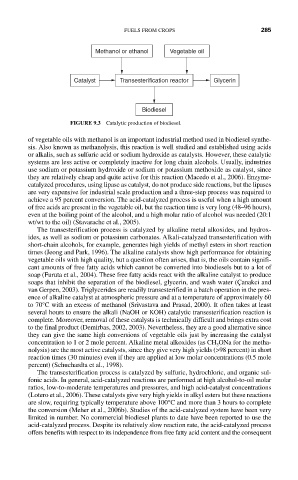

FIGURE 9.3 Catalytic production of biodiesel.

of vegetable oils with methanol is an important industrial method used in biodiesel synthe-

sis. Also known as methanolysis, this reaction is well studied and established using acids

or alkalis, such as sulfuric acid or sodium hydroxide as catalysts. However, these catalytic

systems are less active or completely inactive for long chain alcohols. Usually, industries

use sodium or potassium hydroxide or sodium or potassium methoxide as catalyst, since

they are relatively cheap and quite active for this reaction (Macedo et al., 2006). Enzyme-

catalyzed procedures, using lipase as catalyst, do not produce side reactions, but the lipases

are very expensive for industrial scale production and a three-step process was required to

achieve a 95 percent conversion. The acid-catalyzed process is useful when a high amount

of free acids are present in the vegetable oil, but the reaction time is very long (48–96 hours),

even at the boiling point of the alcohol, and a high molar ratio of alcohol was needed (20:1

wt/wt to the oil) (Stavarache et al., 2005).

The transesterification process is catalyzed by alkaline metal alkoxides, and hydrox-

ides, as well as sodium or potassium carbonates. Alkali-catalyzed transesterification with

short-chain alcohols, for example, generates high yields of methyl esters in short reaction

times (Jeong and Park, 1996). The alkaline catalysts show high performance for obtaining

vegetable oils with high quality, but a question often arises, that is, the oils contain signifi-

cant amounts of free fatty acids which cannot be converted into biodiesels but to a lot of

soap (Furuta et al., 2004). These free fatty acids react with the alkaline catalyst to produce

soaps that inhibit the separation of the biodiesel, glycerin, and wash water (Çanakci and

van Gerpen, 2003). Triglycerides are readily transesterified in a batch operation in the pres-

ence of alkaline catalyst at atmospheric pressure and at a temperature of approximately 60

to 70°C with an excess of methanol (Srivastava and Prasad, 2000). It often takes at least

several hours to ensure the alkali (NaOH or KOH) catalytic transesterification reaction is

complete. Moreover, removal of these catalysts is technically difficult and brings extra cost

to the final product (Demirbas, 2002, 2003). Nevertheless, they are a good alternative since

they can give the same high conversions of vegetable oils just by increasing the catalyst

concentration to 1 or 2 mole percent. Alkaline metal alkoxides (as CH ONa for the metha-

3

nolysis) are the most active catalysts, since they give very high yields (>98 percent) in short

reaction times (30 minutes) even if they are applied at low molar concentrations (0.5 mole

percent) (Schuchardta et al., 1998).

The transesterification process is catalyzed by sulfuric, hydrochloric, and organic sul-

fonic acids. In general, acid-catalyzed reactions are performed at high alcohol-to-oil molar

ratios, low-to-moderate temperatures and pressures, and high acid-catalyst concentrations

(Lotero et al., 2006). These catalysts give very high yields in alkyl esters but these reactions

are slow, requiring typically temperature above 100°C and more than 3 hours to complete

the conversion (Meher et al., 2006b). Studies of the acid-catalyzed system have been very

limited in number. No commercial biodiesel plants to date have been reported to use the

acid-catalyzed process. Despite its relatively slow reaction rate, the acid-catalyzed process

offers benefits with respect to its independence from free fatty acid content and the consequent