Page 301 - Synthetic Fuels Handbook

P. 301

FUELS FROM CROPS 287

MeOH recovery

Water MeOH

Purification

Oil phase

Oils/fats Reactor 1 Reactor 2

Subcritical water Subcritical MeOH

(270°C/7 MPa) (270°C/7 MPa)

Biodiesel

Waste

water

Water phase

Glycerol

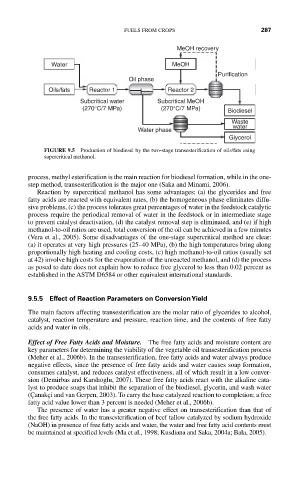

FIGURE 9.5 Production of biodiesel by the two-stage transesterification of oils/fats using

supercritical methanol.

process, methyl esterification is the main reaction for biodiesel formation, while in the one-

step method, transesterification is the major one (Saka and Minami, 2006).

Reaction by supercritical methanol has some advantages: (a) the glycerides and free

fatty acids are reacted with equivalent rates, (b) the homogeneous phase eliminates diffu-

sive problems, (c) the process tolerates great percentages of water in the feedstock catalytic

process require the periodical removal of water in the feedstock or in intermediate stage

to prevent catalyst deactivation, (d) the catalyst removal step is eliminated, and (e) if high

methanol-to-oil ratios are used, total conversion of the oil can be achieved in a few minutes

(Vera et al., 2005). Some disadvantages of the one-stage supercritical method are clear:

(a) it operates at very high pressures (25–40 MPa), (b) the high temperatures bring along

proportionally high heating and cooling costs, (c) high methanol-to-oil ratios (usually set

at 42) involve high costs for the evaporation of the unreacted methanol, and (d) the process

as posed to date does not explain how to reduce free glycerol to less than 0.02 percent as

established in the ASTM D6584 or other equivalent international standards.

9.5.5 Effect of Reaction Parameters on Conversion Yield

The main factors affecting transesterification are the molar ratio of glycerides to alcohol,

catalyst, reaction temperature and pressure, reaction time, and the contents of free fatty

acids and water in oils.

Effect of Free Fatty Acids and Moisture. The free fatty acids and moisture content are

key parameters for determining the viability of the vegetable oil transesterification process

(Meher et al., 2006b). In the transesterification, free fatty acids and water always produce

negative effects, since the presence of free fatty acids and water causes soap formation,

consumes catalyst, and reduces catalyst effectiveness, all of which result in a low conver-

sion (Demirbas and Karslıoglu, 2007). These free fatty acids react with the alkaline cata-

lyst to produce soaps that inhibit the separation of the biodiesel, glycerin, and wash water

(Çanakçi and van Gerpen, 2003). To carry the base catalyzed reaction to completion; a free

fatty acid value lower than 3 percent is needed (Meher et al., 2006b).

The presence of water has a greater negative effect on transesterification than that of

the free fatty acids. In the transesterification of beef tallow catalyzed by sodium hydroxide

(NaOH) in presence of free fatty acids and water, the water and free fatty acid contents must

be maintained at specified levels (Ma et al., 1998; Kusdiana and Saka, 2004a; Bala, 2005).