Page 100 - TPM A Route to World-Class Performance

P. 100

The TPM improvement plan 81

0 Potential improvement The first improvement objective is to obtain

consistently, through standardization and stabilization, the best of the

best in each of the three categories: availability, performance and quality.

Beyond this point there must be continuous improvement towards world-

class levels.

The OEE formula is as follows:

Overall availability performance quality rate

equipment = of the x rate when x of product

effectiveness asset running produced

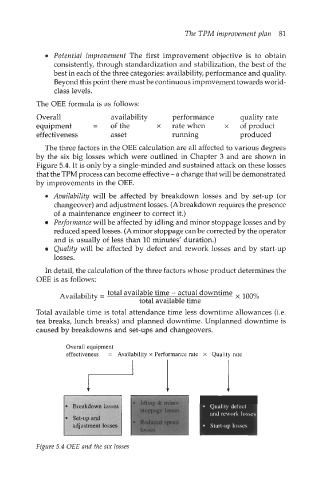

The three factors in the OEE calculation are all affected to various degrees

by the six big losses which were outlined in Chapter 3 and are shown in

Figure 5.4. It is only by a single-minded and sustained attack on these losses

that the TPM process can become effective - a change that will be demonstrated

by improvements in the OEE.

0 Availability will be affected by breakdown losses and by set-up (or

changeover) and adjustment losses. (A breakdown requires the presence

of a maintenance engineer to correct it.)

Performance will be affected by idling and minor stoppage losses and by

reduced speed losses. (A minor stoppage can be corrected by the operator

and is usually of less than 10 minutes’ duration.)

Quality will be affected by defect and rework losses and by start-up

losses.

In detail, the calculation of the three factors whose product determines the

OEE is as follows:

total available time - actual downtime

Availability = looyo

total available time

Total available time is total attendance time less downtime allowances (i.e.

tea breaks, lunch breaks) and planned downtime. Unplanned downtime is

caused by breakdowns and set-ups and changeovers.

Overall equipment

effectiveness = Availability x Performance rate x Quality rate

Figure 5.4 OEE and the six losses