Page 151 - TPM A Route to World-Class Performance

P. 151

130 TPM-A Route to World-Class Performance

Set-up and Reduced Start-up

changeover speed losses

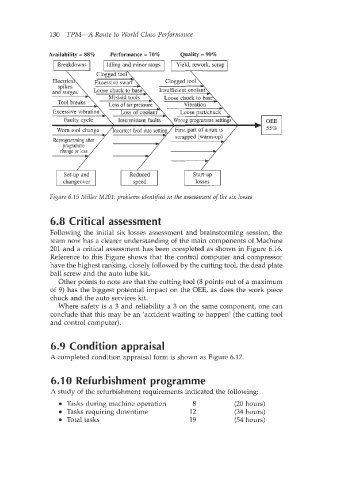

Figure 6.15 Miller M201: problems identifed in the assessment of the six losses

6.8 Critical assessment

Following the initial six losses assessment and brainstorming session, the

team now has a clearer understanding of the main components of Machine

201 and a critical assessment has been completed as shown in Figure 6.16.

Reference to this Figure shows that the control computer and compressor

have the highest ranking, closely followed by the cutting tool, the dead plate

ball screw and the auto lube kit.

Other points to note are that the cutting tool (8 points out of a maximum

of 9) has the biggest potential impact on the OEE, as does the work piece

chuck and the auto services kit.

Where safety is a 3 and reliability a 3 on the same component, one can

conclude that this may be an 'accident waiting to happen' (the cutting tool

and control computer).

6.9 Condition appraisal

A completed condition appraisal form is shown as Figure 6.17

6.1 0 Refurbishment programme

A study of the refurbishment requirements indicated the following:

Tasks during machine operation 8 (20 hours)

Tasks requiring downtime 12 (34 hours)

Total tasks 19 (54 hours)