Page 191 - TPM A Route to World-Class Performance

P. 191

168 TPM-A Route to World-Class Pevformance

discipline teams of five to seven personnel. These teams will direct a minimum

of 5 per cent of their time to continuous improvement.

Organizational learning

Often first line management is perceived as the barrier to change. In reality,

’what gets measured gets attention’. Traditionally first line management is

left alone provided the tonnes go out of the door. Anything else is a ’nice to

have’, and if it doesn’t happen, then it will be ignored.

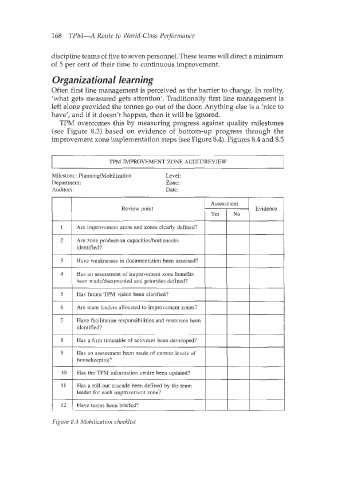

TPM overcomes this by measuring progress against quality milestones

(see Figure 8.3) based on evidence of bottom-up progress through the

improvement zone implementation steps (see Figure 8.4). Figures 8.4 and 8.5

TPM IMPROVEMENT ZONE AUDITREVIEW

Milestone: PlanningMobilization Level:

Department: Zone:

Auditors: Date:

Assessment

Review point Evidence

Yes No

1 Are improvement areas and zones clearly defined?

2 Are zone production capacities/bottlenecks

identified?

I 3 I Have weaknesses in documentation been assessed? I I I I

Has an assessment of improvement zone benefits

been made/documented and priorities defined?

I I I I

5 I Has future TPM vision been clarified?

I l l I

6 I Are team leaders allocated to improvement zones?

Have facilitation responsibilities and resources been

identified?

8 I Has a firm timetable of activities been developed? I I n

Has an assessment been made of current levels of

housekeeping?

10 Has the TPM information centre been updated?

l1 I Has a roll-out cascade been defined by the team I

leader for each improvement zone?

12 1 Have teams been briefed? I 1 -

Figure 8.4 Mobilization checklist