Page 187 - TPM A Route to World-Class Performance

P. 187

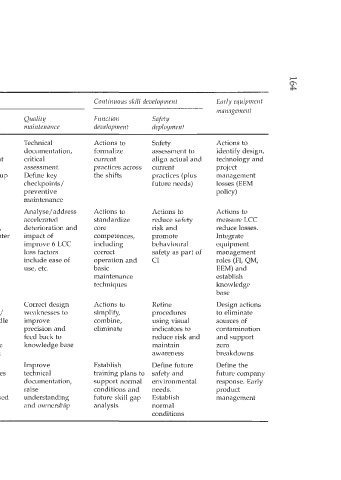

Table 7.2 TPM bottom-up standards

Step OEF OAC MAC Coritrnzious skill development Early equipinent

iriaiiagemei? t

Lvss Focused Plaiined Qualily Function Safety

deployment irriprouerneiit maintenance maintenance development deployinent

Highlight loss Support technical Initial cleaning Maintenance Teclmical Actions to Safety Actions to

levels, priorities problcm/improvement of workplace WPO documentation, formalize assessment to identify design,

KPIs, cross-shift activities in initial roll- and refurbishment critical current align actual and technology and

accountabilities out phases to equipment/ and critical assessment. practices across current project

and progress address sources of condition system back-up Define key the shifts practices (plus management

reporting contamination appraisal routines checkpoints/ future needs) losses (EEM

preventive policy)

maintenance

Establish team- Transfer lessons Action of Contain Analyse/address Actions to Actions to Actions to

based across similar source, accelerated accelerated standardize reduce safety measure LCC

performance equipment including deterioration, deterioration and core risk and reduce losses.

management at cleaning and develop counter impact of competences, promote Integrate

all levels linked use of SPLs measure, improve 6 LCC including behavioural equipment

to the current including loss factors correct safety as part of management

year business correct include ease of operation and CI roles (FI, QM,

planning parameter use, etc. basic EEM) and

process setting maintenance establish

techniques knowledge

base

Integrate future Focus on support Adopt apple a Set Correct design Actions to Refine Design actions

business problem/iinprovement day standards thermom etcr / weaknesses to simplify, procedures to eliminate

planning with activities, including and use of injection needle improve combine, using visual sources of

PDP and PDP targets visual standards to precision and eliminate indicators to contamination

specific loss indicators improve feed back to reduce risk and and support

reduction response tune knowledge base maintain zero

targets and feedback awareness breakdowns

Define future Assess supply chain Adopt Eliminate Improve Establish Define future Define the

loss vision losses. Define the thermometer sporadic losses technical training plans to safety and future company

linked to exceed future customer standards (breakdown documentation, support normal environmental response. Early

future customer requirements analysis, raise conditions and needs. product

expectations condition-based understanding future skill gap Establish management

repla cem en t) and ownership analysis normal

conditions