Page 145 - Tandem Techniques

P. 145

Page 126

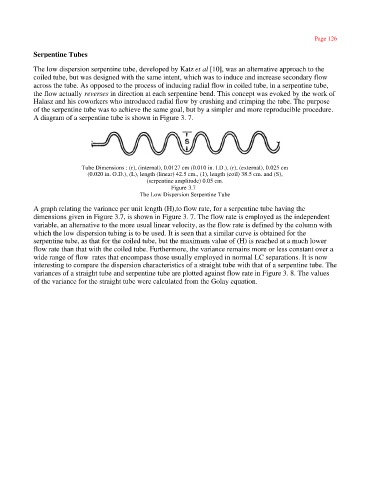

Serpentine Tubes

The low dispersion serpentine tube, developed by Katz et al [10], was an alternative approach to the

coiled tube, but was designed with the same intent, which was to induce and increase secondary flow

across the tube. As opposed to the process of inducing radial flow in coiled tube, in a serpentine tube,

the flow actually reverses in direction at each serpentine bend. This concept was evoked by the work of

Halasz and his coworkers who introduced radial flow by crushing and crimping the tube. The purpose

of the serpentine tube was to achieve the same goal, but by a simpler and more reproducible procedure.

A diagram of a serpentine tube is shown in Figure 3. 7.

Tube Dimensions : (r), (internal), 0.0127 cm (0.010 in. I.D.), (r), (external), 0.025 cm

(0.020 in. O.D.), (L), length (linear) 42.5 cm., (1), length (coil) 38.5 cm. and (S),

(serpentine amplitude) 0.05 cm.

Figure 3.7

The Low Dispersion Serpentine Tube

A graph relating the variance per unit length (H),to flow rate, for a serpentine tube having the

dimensions given in Figure 3.7, is shown in Figure 3. 7. The flow rate is employed as the independent

variable, an alternative to the more usual linear velocity, as the flow rate is defined by the column with

which the low dispersion tubing is to be used. It is seen that a similar curve is obtained for the

serpentine tube, as that for the coiled tube, but the maximum value of (H) is reached at a much lower

flow rate than that with the coiled tube. Furthermore, the variance remains more or less constant over a

wide range of flow rates that encompass those usually employed in normal LC separations. It is now

interesting to compare the dispersion characteristics of a straight tube with that of a serpentine tube. The

variances of a straight tube and serpentine tube are plotted against flow rate in Figure 3. 8. The values

of the variance for the straight tube were calculated from the Golay equation.