Page 256 - The Combined Finite-Discrete Element Method

P. 256

DISCRETE CRACK MODEL 239

The problem of sensitivity to mesh orientation remains, and it is not easy to provide an

answer to the question of the extent to which the obtained fracture pattern is a function

of the initial mesh. This is because the final fracture pattern does not depend only on

the initial mesh, but also on all subsequent remeshings, which are in turn governed by

the creation of new boundaries. In other words, the mesh pattern is influenced by mesh

orientation, and in turn the transient meshes are a result of boundaries created by the frac-

ture pattern. The problem of sensitivity of the fracture pattern to mesh orientation in the

context of the smeared fracture and fragmentation model is also coupled with algorithmic

complexities involving permanent remeshing due to the creation of new boundaries and

the problems associated with it (transfer of variables, tracing of new contacts, perma-

nently changing size, topology and CPU and RAM requirements during execution of the

computer problem). Thus, in recent developments of the combined finite-discrete element

method, the emphasis is being placed on discrete crack based approaches.

7.3 DISCRETE CRACK MODEL

As explained above, the smeared crack model for fracture and fragmentation is cou-

pled with numerical difficulties and algorithmic complexities. Bearing in mind the other

complexities involved in combined finite-discrete element simulations, such as contact

detection and contact interaction, the transition from continua to discontinua algorithms

must be optimised both in terms of CPU time and RAM requirements. Recent research

efforts regarding fracture modelling in the context of the combined finite-discrete element

method have therefore also included the single crack model. The model presented in this

section is actually a combination of the smeared and single crack approaches. It was

designed with the aim of modelling multiple-crack situations, progressive fracture and

failure, including fragmentation and the creation of a large number of rock fragments of

general shape and size.

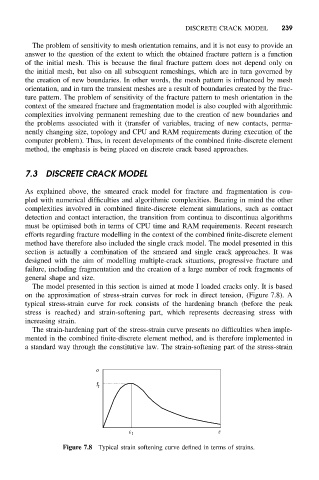

The model presented in this section is aimed at mode I loaded cracks only. It is based

on the approximation of stress-strain curves for rock in direct tension, (Figure 7.8). A

typical stress-strain curve for rock consists of the hardening branch (before the peak

stress is reached) and strain-softening part, which represents decreasing stress with

increasing strain.

The strain-hardening part of the stress-strain curve presents no difficulties when imple-

mented in the combined finite-discrete element method, and is therefore implemented in

a standard way through the constitutive law. The strain-softening part of the stress-strain

s

f t

e t e

Figure 7.8 Typical strain softening curve defined in terms of strains.