Page 12 - The Geological Interpretation of Well Logs

P. 12

- THE GEOLOGICAL INTERPRETATION OF WELL LOGS -

Table 1.1 Classification of the common wireline geophysical well measurements (in ‘open hole’).

Log Type Formation parameter measured

Mechanical measurements Caliper Hole diameter

Spontaneous measurements Temperature Borehole temperature

SP (self-patential} Spontaneous electrical currents

Gamma ray Natural radioactivity

Induced measurements Resistivity Resistance to electrical current

Induction Conductivity of electrical current

Sonic Velocity of sound propagation

Density Reaction to gamma ray bombardment

Photoelectric Reaction to gamma ray bombardment

Neutron Reaction to neutron bombardment

{measurement while drilling) or LWD (logging while

drilling) logs, by contrast, are made as a formation is

drilled. Quite different techniques are made to record magnatic

recording

MWD and LWD logs but the results are comparable to

the open hole wireline logs (see Section 1.6).

(0) (0) mechanical

Wireline logs are made using highly specialized equip- Geog winchiag

drum

ment entirely separate from that used for drilling.

Onshore, a motorized logging truck is used which brings logging

VAS cable

its array of surface recorders, computers and a logging

drum and cable to the drill site. Offshore, the sarne equip- a

ment is installed in a small cabin left permanently on the =<

Z

rig. Both truck and cabin use a variety of interchangeable

logging tools, which are lowered into the wel] on the Y

logging cable (Figure 1.2). U; vat an

Most modern logs are recorded digitally. The sam-

pling rate will normally be once every 15 cm (6 in),

although for some specialized logs it will be as low as 2.5

surtace

mm {0.1 in). An average well of say 2000 m will there- computer

fore be sampled over 12,000 times for each individual

tog, and for a suite of 8 or so typical logs, it will be

sampled over 100,000 times (although for some new,

specialised tools, this can be the sampling rate per WZ 1 down hole

metre!). At typical logging speeds, data transmission logging

tool

rates will vary from 0.05 kilobits per second for simpler

logs to over 200 kilobits per second for the new complex SN

logs. The huge amount of data representing each logging

run is fed into the computer of the surface unit. There is

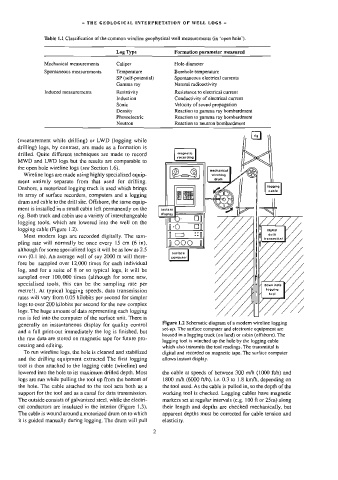

Figure 1.2 Schematic diagram of a modern wireline logging

generally an instantaneous display for quality control

set-up, The surface computer and etectronic equipment are

and a full print-out immediately the log is finished, but

housed in a logging truck {on land) or cabin (offshore). The

the raw data are stored on magnetic tape for future pro-

logging tool is winched up the hole by the logging cable

cessing and editing.

which also transmits the tool readings. The transmittal is

To run wireline logs, the hole is cleaned and stabilized digital and recorded on magnetic tape. The surface computer

and the drilling equipment extracted The first logging allows instant display.

tool is then attached to the logging cable (wireline) and

lowered into the hole to its maximum drilled depth. Most the cable at speeds of between 300 mvh (1000 ft/h) and

logs are run while pulling the tool up from the bottom of 1800 m/h (6000 ft/h), ie. 0.3 to 1.8 km/h, depending on

the hole. The cable attached to the tool acts both as a the tool used. As the cable is pulled in, so the depth of the

support for the too] and as a canal for data transmission. working tool is checked. Logging cables have magnetic

The outside consists of galvanized steel, while the electri- markers set at regular intervals (e.g. 100 ft or 25m) along

cal conductors are insulated in the interior (Figure 1.3). their length and depths are checked mechanically, but

The cable is wound around a motorized drum on to which apparent depths must be corrected for cable tension and

it is guided manually during logging. The drum will pult elasticity.