Page 240 - The Jet Engine

P. 240

Manufacture

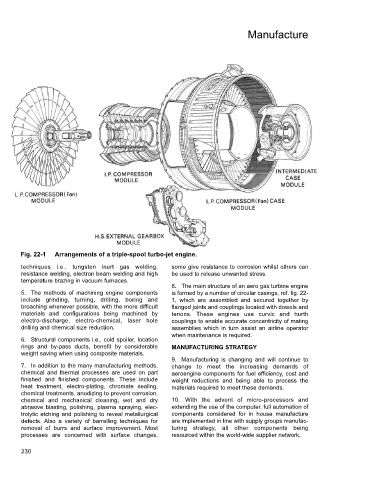

Fig. 22-1 Arrangements of a triple-spool turbo-jet engine.

techniques i.e., tungsten inert gas welding, some give resistance to corrosion whilst others can

resistance welding, electron beam welding and high be used to release unwanted stress.

temperature brazing in vacuum furnaces.

8. The main structure of an aero gas turbine engine

5. The methods of machining engine components is formed by a number of circular casings, ref. fig. 22-

include grinding, turning, drilling, boring and 1, which are assembled and secured together by

broaching whenever possible, with the more difficult flanged joints and couplings located with dowels and

materials and configurations being machined by tenons. These engines use curvic and hurth

electro-discharge, electro-chemical, laser hole couplings to enable accurate concentricity of mating

drilling and chemical size reduction. assemblies which in turn assist an airline operator

when maintenance is required.

6. Structural components i.e., cold spoiler, location

rings and by-pass ducts, benefit by considerable MANUFACTURING STRATEGY

weight saving when using composite materials.

9. Manufacturing is changing and will continue to

7. In addition to the many manufacturing methods, change to meet the increasing demands of

chemical and thermal processes are used on part aeroengine components for fuel efficiency, cost and

finished and finished components. These include weight reductions and being able to process the

heat treatment, electro-plating, chromate sealing, materials required to meet these demands.

chemical treatments, anodizing to prevent corrosion,

chemical and mechanical cleaning, wet and dry 10. With the advent of micro-processors and

abrasive blasting, polishing, plasma spraying, elec- extending the use of the computer, full automation of

trolytic etching and polishing to reveal metallurgical components considered for in house manufacture

defects. Also a variety of barrelling techniques for are implemented in line with supply groups manufac-

removal o! burrs and surface improvement. Most turing strategy, all other components being

processes are concerned with surface changes, resourced within the world-wide supplier network.

230