Page 243 - The Jet Engine

P. 243

Manufacture

17. Forging calls for a very close control of the

temperature during the various operations. An

exceptionally high standard of furnace control

equipment, careful maintenance and cleanliness of

the forging hammers, presses and dies, is essential.

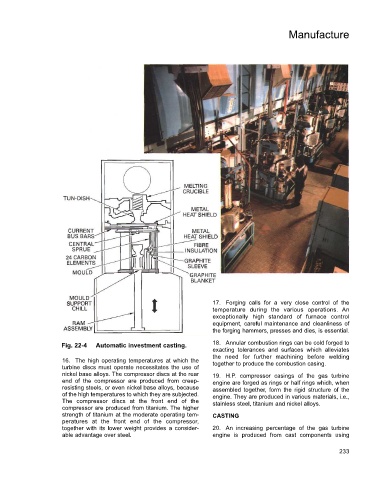

Fig. 22-4 Automatic investment casting. 18. Annular combustion rings can be cold forged to

exacting tolerances and surfaces which alleviates

the need for further machining before welding

16. The high operating temperatures at which the together to produce the combustion casing.

turbine discs must operate necessitates the use of

nickel base alloys. The compressor discs at the rear 19. H.P. compressor casings of the gas turbine

end of the compressor are produced from creep- engine are forged as rings or half rings which, when

resisting steels, or even nickel base alloys, because assembled together, form the rigid structure of the

of the high temperatures to which they are subjected. engine. They are produced in various materials, i.e.,

The compressor discs at the front end of the stainless steel, titanium and nickel alloys.

compressor are produced from titanium. The higher

strength of titanium at the moderate operating tem- CASTING

peratures at the front end of the compressor,

together with its lower weight provides a consider- 20. An increasing percentage of the gas turbine

able advantage over steel. engine is produced from cast components using

233