Page 246 - The Jet Engine

P. 246

Manufacture

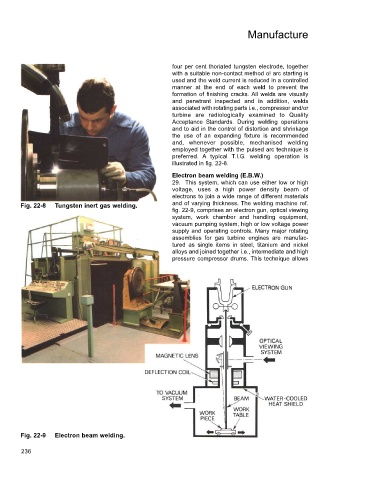

four per cent thoriated tungsten electrode, together

with a suitable non-contact method o! arc starting is

used and the weld current is reduced in a controlled

manner at the end of each weld to prevent the

formation of finishing cracks. All welds are visually

and penetrant inspected and in addition, welds

associated with rotating parts i.e., compressor and/or

turbine are radiologically examined to Quality

Acceptance Standards. During welding operations

and to aid in the control of distortion and shrinkage

the use of an expanding fixture is recommended

and, whenever possible, mechanised welding

employed together with the pulsed arc technique is

preferred. A typical T.I.G. welding operation is

illustrated in fig. 22-8.

Electron beam welding (E.B.W.)

29. This system, which can use either low or high

voltage, uses a high power density beam of

electrons to join a wide range of different materials

Fig. 22-8 Tungsten inert gas welding. and of varying thickness. The welding machine ref.

fig. 22-9, comprises an electron gun, optical viewing

system, work chamber and handling equipment,

vacuum pumping system, high or low voltage power

supply and operating controls. Many major rotating

assemblies for gas turbine engines are manufac-

tured as single items in steel, titanium and nickel

alloys and joined together i.e., intermediate and high

pressure compressor drums. This technique allows

Fig. 22-9 Electron beam welding.

236