Page 248 - The Jet Engine

P. 248

Manufacture

Stem drilling

35. This process consists of tubes (cathode)

produced from titanium and suitably insulated to

ensure a reaction at the tip. A twenty per cent

solution of nitric acid is fed under pressure onto the

blade producing holes generally in the region of

0.026 in. diameter. The process is more speedy in

operation than electro-discharge machining and is

capable of drilling holes up to a depth two hundred

times the diameter of the tube in use.

Capillary drilling

36. Similar in process to stem drilling but using

tubes produced from glass incorporating a core of

platinum wire (cathode). A twenty per cent nitric acid

solution is passed through the tube onto the

workpiece and is capable of producing holes as

small as 0.009 in. diameter. Depth of the hole is up

to forty times greater than the tube in use and

therefore determined by tube diameter.

37. Automation has also been added to the process

of electro-chemical machining (E.C.M.) with the intro-

duction of 360 degree E.G. machining of small

compressor blades, ref. fig. 22-12. For some blades

of shorter length airfoil, this technique is more cost

effective than the finished shaped airfoil when using

precision forging techniques. Blades produced by

E.C.M. employ integrated vertical broaching

machines which take pre-cut lengths of bar material,

produce the blade root feature, such as a fir-tree, and

then by using this as the location, fully E.C.M. from

both sides to produce the thin airfoil section in one

operation.

ELECTRO-DISCHARGE MACHINING (E.D.M.)

38. This type of machining removes metal from the

workpiece by converting the kinetic energy of electric

sparks into heat as the sparks strike the workpiece.

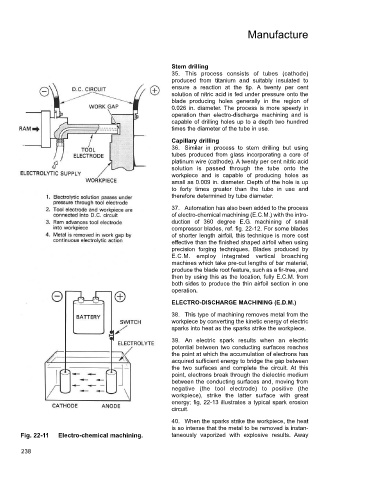

39. An electric spark results when an electric

potential between two conducting surfaces reaches

the point at which the accumulation of electrons has

acquired sufficient energy to bridge the gap between

the two surfaces and complete the circuit. At this

point, electrons break through the dielectric medium

between the conducting surfaces and, moving from

negative (the tool electrode) to positive (the

workpiece), strike the latter surface with great

energy; fig, 22-13 illustrates a typical spark erosion

circuit.

40. When the sparks strike the workpiece, the heat

is so intense that the metal to be removed is instan-

Fig. 22-11 Electro-chemical machining. taneously vaporized with explosive results. Away

238