Page 247 - The Jet Engine

P. 247

Manufacture

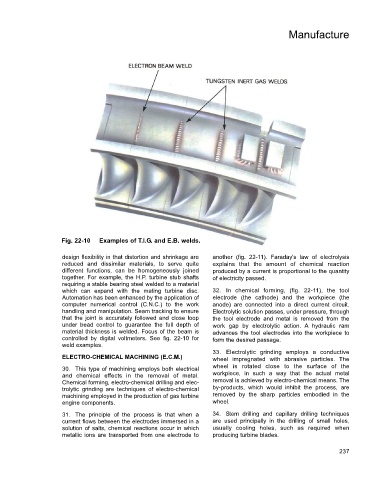

Fig. 22-10 Examples of T.I.G. and E.B. welds.

design flexibility in that distortion and shrinkage are another (fig. 22-11). Faraday's law of electrolysis

reduced and dissimilar materials, to serve quite explains that the amount of chemical reaction

different functions, can be homogeneously joined produced by a current is proportional to the quantity

together. For example, the H.P. turbine stub shafts of electricity passed.

requiring a stable bearing steel welded to a material

which can expand with the mating turbine disc. 32. In chemical forming, (fig. 22-11), the tool

Automation has been enhanced by the application of electrode (the cathode) and the workpiece (the

computer numerical control (C.N.C.) to the work anode) are connected into a direct current circuit.

handling and manipulation. Seam tracking to ensure Electrolytic solution passes, under pressure, through

that the joint is accurately followed and close loop the tool electrode and metal is removed from the

under bead control to guarantee the full depth of work gap by electrolytic action. A hydraulic ram

material thickness is welded. Focus of the beam is advances the tool electrodes into the workpiece to

controlled by digital voltmeters. See fig. 22-10 for form the desired passage.

weld examples.

33. Electrolytic grinding employs a conductive

ELECTRO-CHEMICAL MACHINING (E.C.M.) wheel impregnated with abrasive particles. The

30. This type of machining employs both electrical wheel is rotated close to the surface of the

and chemical effects in the removal of metal. workpiece, in such a way that the actual metal

Chemical forming, electro-chemical drilling and elec- removal is achieved by electro-chemical means. The

trolytic grinding are techniques of electro-chemical by-products, which would inhibit the process, are

machining employed in the production of gas turbine removed by the sharp particles embodied in the

engine components. wheel.

31. The principle of the process is that when a 34. Stem drilling and capillary drilling techniques

current flows between the electrodes immersed in a are used principally in the drilling of small holes,

solution of salts, chemical reactions occur in which usually cooling holes, such as required when

metallic ions are transported from one electrode to producing turbine blades.

237