Page 245 - The Jet Engine

P. 245

Manufacture

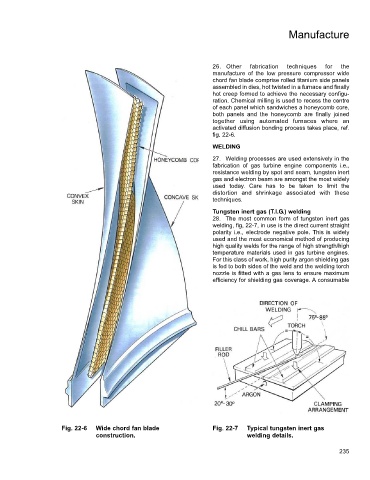

26. Other fabrication techniques for the

manufacture of the low pressure compressor wide

chord fan blade comprise rolled titanium side panels

assembled in dies, hot twisted in a furnace and finally

hot creep formed to achieve the necessary configu-

ration. Chemical milling is used to recess the centre

of each panel which sandwiches a honeycomb core,

both panels and the honeycomb are finally joined

together using automated furnaces where an

activated diffusion bonding process takes place, ref.

fig. 22-6.

WELDING

27. Welding processes are used extensively in the

fabrication of gas turbine engine components i.e.,

resistance welding by spot and seam, tungsten inert

gas and electron beam are amongst the most widely

used today. Care has to be taken to limit the

distortion and shrinkage associated with these

techniques.

Tungsten inert gas (T.I.G.) welding

28. The most common form of tungsten inert gas

welding, fig, 22-7, in use is the direct current straight

polarity i.e., electrode negative pole. This is widely

used and the most economical method of producing

high quality welds for the range of high strength/high

temperature materials used in gas turbine engines.

For this class of work, high purity argon shielding gas

is fed to both sides of the weld and the welding torch

nozzle is fitted with a gas lens to ensure maximum

efficiency for shielding gas coverage. A consumable

Fig. 22-6 Wide chord fan blade Fig. 22-7 Typical tungsten inert gas

construction. welding details.

235