Page 61 - The Jet Engine

P. 61

11. The losses which prevent the turbine from being

100 per cent efficient are due to a number of

reasons. A typical uncooled three-stage turbine

would suffer a 3.5 per cent loss because of

aerodynamic losses in the turbine blades. A further

4.5 per cent loss would be incurred by aerodynamic

losses in the nozzle guide vanes, gas leakage over

the turbine blade tips and exhaust system losses;

these losses are of approximately equal proportions.

The total losses result in an overall efficiency of

approximately 92 per cent.

CONSTRUCTION

12. The basic components of the turbine are the

combustion discharge nozzles, the nozzle guide

vanes, the turbine discs and the turbine blades. The

rotating assembly is carried on bearings mounted in

the turbine casing and the turbine shaft may be

common to the compressor shaft or connected to it

by a self-aligning coupling.

Nozzle guide vanes

13. The nozzle guide vanes are of an aerofoil shape

with the passage between adjacent vanes forming a

convergent duct. The vanes are located (fig. 5-8) in

Fig. 5-6 A typical turbine blade showing the turbine casing in a manner that allows for

twisted contour. expansion.

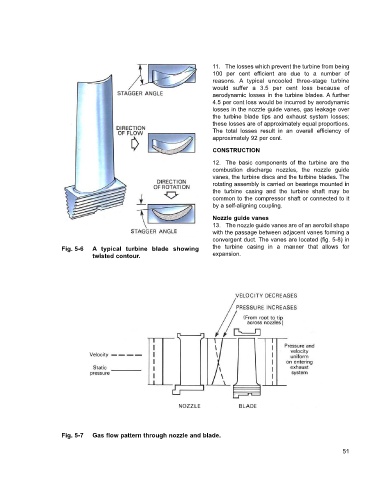

Fig. 5-7 Gas flow pattern through nozzle and blade.

51