Page 62 - The Jet Engine

P. 62

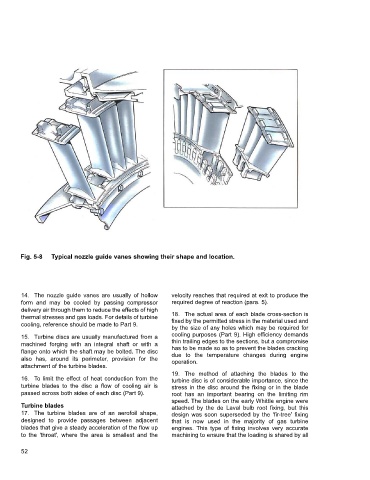

Fig. 5-8 Typical nozzle guide vanes showing their shape and location.

14. The nozzle guide vanes are usually of hollow velocity reaches that required at exit to produce the

form and may be cooled by passing compressor required degree of reaction (para. 5).

delivery air through them to reduce the effects of high

thermal stresses and gas loads. For details of turbine 18. The actual area of each blade cross-section is

fixed by the permitted stress in the material used and

cooling, reference should be made to Part 9.

by the size of any holes which may be required for

15. Turbine discs are usually manufactured from a cooling purposes (Part 9). High efficiency demands

machined forging with an integral shaft or with a thin trailing edges to the sections, but a compromise

flange onto which the shaft may be bolted. The disc has to be made so as to prevent the blades cracking

due to the temperature changes during engine

also has, around its perimeter, provision for the operation.

attachment of the turbine blades.

19. The method of attaching the blades to the

16. To limit the effect of heat conduction from the turbine disc is of considerable importance, since the

turbine blades to the disc a flow of cooling air is stress in the disc around the fixing or in the blade

passed across both sides of each disc (Part 9). root has an important bearing on the limiting rim

speed. The blades on the early Whittle engine were

Turbine blades attached by the de Laval bulb root fixing, but this

17. The turbine blades are of an aerofoil shape, design was soon superseded by the 'fir-tree' fixing

designed to provide passages between adjacent that is now used in the majority of gas turbine

blades that give a steady acceleration of the flow up engines. This type of fixing involves very accurate

to the 'throat', where the area is smallest and the machining to ensure that the loading is shared by all

52