Page 111 -

P. 111

The Practical Pumping Handbook

TERTIARY

_~,~' SEAL/

Stuffing Box ,...........,....<

~/////////] Rot at ln g [~!~ii:i-i-i~:!i:!-!-i-i~

Stationary

Face

PRIMARY

Pump Shaft SECONDARY SEAL

SEAL

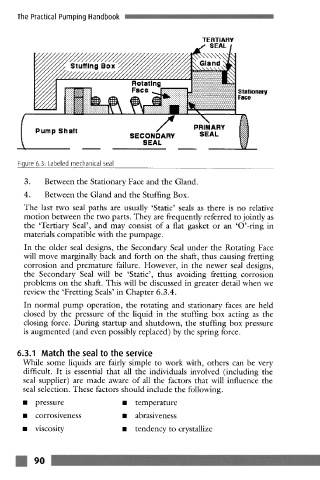

Figure 6.3: Labeled mechanical seal

Between the Stationary Face and the Gland.

.

Between the Gland and the Stuffing Box.

.

The last two seal paths are usually 'Static' seals as there is no relative

motion between the two parts. They are frequently referred to jointly as

the 'Tertiary Seal', and may consist of a flat gasket or an 'O'-ring in

materials compatible with the pumpage.

In the older seal designs, the Secondary Seal under the Rotating Face

will move marginally back and forth on the shaft, thus causing fretting

corrosion and premature failure. However, in the newer seal designs,

the Secondary Seal will be 'Static', thus avoiding fretting corrosion

problems on the shaft. This will be discussed in greater detail when we

review the 'Fretting Seals' in Chapter 6.3.4.

In normal pump operation, the rotating and stationary faces are held

closed by the pressure of the liquid in the stuffing box acting as the

closing force. During startup and shutdown, the stuffing box pressure

is augmented (and even possibly replaced) by the spring force.

6.3.1 Match the seal to the service

While some liquids are fairly simple to work with, others can be very

difficult. It is essential that all the individuals involved (including the

seal supplier) are made aware of all the factors that will influence the

seal selection. These factors should include the following.

9 pressure 9 temperature

9 corrosiveness 9 abrasiveness

9 viscosity 9 tendency to crystallize

m 90