Page 109 -

P. 109

The Practical Pumping Handbook .......................................................................................................................................... 7o_ -T .......... 7m

( )ii)ii""

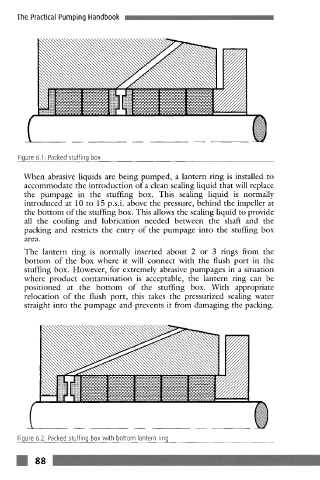

Figure 6.1: Packed stuffing box

When abrasive liquids arc being pumped, a lantern ring is installed to

accommodate the introduction of a clean sealing liquid that will replace

the pumpagc in the stuffing box. This sealing liquid is normally

introduced at 10 to 15 p.s.i, above the pressure, behind the impeller at

the bottom of the stuffing box. This allows the scaling liquid to provide

all thc cooling and lubrication needed between the shaft and the

packing and restricts the entry of the pumpage into the stuffing box

area.

The lantern ring is normally inserted about 2 or 3 rings from the

bottom of the box where it will connect with the flush port in the

stuffing box. However, for extremely abrasive pumpages in a situation

where product contamination is acceptable, the lantern ring can be

positioned at the bottom of the stuffing box. With appropriate

relocation of the flush port, this takes the pressurized sealing water

straight into the pumpage and prevents it from damaging the pacldng.

( Q

Figure 6.2: Packed stuffing box with bottom lantern ring

m 88