Page 112 -

P. 112

']]rrrr stuffing Box Sealing

YES Is 1he Uquid Toxic?

No

Yes Is there Abrasive SlighlJy / ,._1 Cyclone SeparalDr

1,o .. 1,o

Conl~nt? "-I appropnale?

!

Yes Dues 1he Uquid ] Clean Rush

Crysl~lize? I from ex~ma] source

appropdal~?

!

No ,App~prial~? Yes contacts alrnusphem I

Is a Quench

When 1he Uquid

Sl~arn or Uquicl? is it Inflammable I

or Corrosive?

Yes I l~'J~

v f

Consider: Considel: Consider: Consider:

Double Seal & Single Inside Seal Single Inside Single Inside Sea] &

Barrier Ruid Rush and Quench or Outside Sea] Extema] Clean Rush

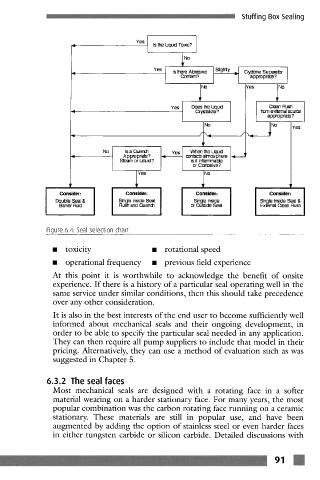

Figure 6.4: Seal selection chart

9 toxicity 9 rotational speed

9 operational frequency 9 previous field experience

At this point it is worthwhile to acknowledge the benefit of onsite

experience. If there is a history of a particular seal operating well in the

same service under similar conditions, then this should take precedence

over any other consideration.

It is also in the best interests of the end user to become sufficiently well

informed about mechanical seals and their ongoing development, in

order to be able to specify the particular seal needed in any application.

They can then require all pump suppliers to include that model in their

pricing. Alternatively, they can use a method of evaluation such as was

suggested in Chapter 5.

6.3.2 The seal faces

Most mechanical seals are designed with a rotating face in a softer

material wearing on a harder stationary face. For many years, the most

popular combination was the carbon rotating face running on a ceramic

stationary. These materials arc still in popular use, and have been

augmented by adding the option of stainless steel or even harder faces

in either tungsten carbide or silicon carbide. Detailed discussions with

91