Page 155 -

P. 155

The Practical Pumping Handbook ~- ..._ : ==:~ - ....... - ............................................................

8.2.4.1 Medium density stock pumps

Medium density applications can be handled successfully by a

centrifugal pump. However, this capability is greatly dependent on the

fluidity of the stock and the ability of the system to deliver it freely to

the impeller eye.

Special stock pump designs have been produced and are reputed to be

able to deliver the same head and flow for stock as for water at

consistencies of up to 5-7%. As the power consumption and efficiency

remain almost unchanged, this would result in dramatic reductions in

horsepower requirements.

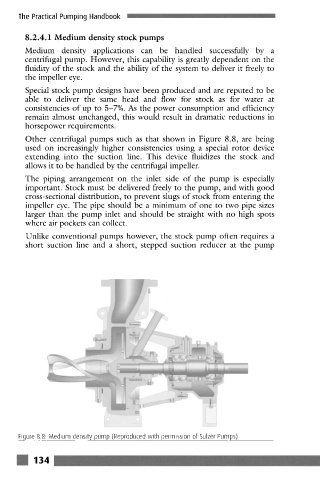

Other centrifugal pumps such as that shown in Figure 8.8, are being

used on increasingly higher consistencies using a special rotor device

extending into the suction line. This device fluidizes the stock and

allows it to be handled by the centrifugal impeller.

The piping arrangement on the inlet side of the pump is especially

important. Stock must be delivered freely to the pump, and with good

cross-sectional distribution, to prevent slugs of stock from entering the

impeller eye. The pipe should be a minimum of one to two pipe sizes

larger than the pump inlet and should be straight with no high spots

where air pockets can collect.

Unlike conventional pumps however, the stock pump often requires a

short suction line and a short, stepped suction reducer at the pump

Figure 8.8. Medium density pump (Reproduced with permission of Sulzer Pumps)

134 ~ ............................................................ : ............................