Page 156 -

P. 156

........................................................... Special Applications

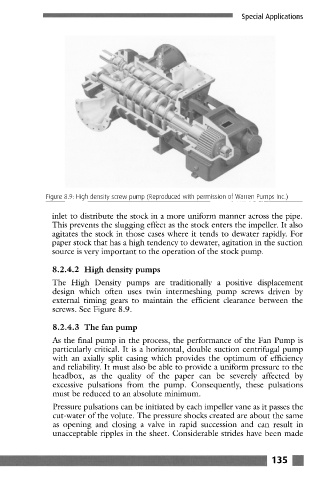

Figure 8.9: High density screw pump (Reproduced with permission of Warren Pumps Inc.)

inlet to distribute the stock in a more uniform manner across the pipe.

This prevents the slugging effect as the stock enters the impeller. It also

agitates the stock in those cases where it tends to dewater rapidly. For

paper stock that has a high tendency to dewater, agitation in the suction

source is very important to the operation of the stock pump.

8.2.4.2 High density pumps

The High Density pumps are traditionally a positive displacement

design which often uses twin intermeshing pump screws driven by

external timing gears to maintain the efficient clearance between the

screws. See Figure 8.9.

8.2.4.3 The fan pump

As the final pump in the process, the performance of the Fan Pump is

particularly critical. It is a horizontal, double suction centrifugal pump

with an axially split casing which provides the optimum of efficiency

and reliability. It must also be able to provide a uniform pressure to the

headbox, as the quality of the paper can be severely affected by

excessive pulsations from the pump. Consequently, these pulsations

must be reduced to an absolute minimum.

Pressure pulsations can be initiated by each impeller vane as it passes the

cut-water of the volute. The pressure shocks created are about the same

as opening and closing a valve in rapid succession and can result in

unacceptable ripples in the sheet. Considerable strides have been made

=__;_____~i ................ Z ..................................................... ! ..... ~ ......................................................... ~ ....... 135 m