Page 178 -

P. 178

Special Pumps

-]

iill

, ff

!

.... i.i.i.ii : -

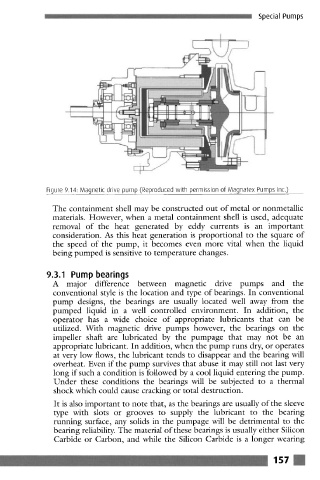

Figure 9.14: Magnetic drive pump (Reproduced with permission of Magnatex Pumps Inc.)

The containment shell may be constructed out of metal or nonmetallic

materials. However, when a metal containment shell is used, adequate

removal of the heat generated by eddy currents is an important

consideration. As this heat generation is proportional to the square of

the speed of the pump, it becomes even more vital when the liquid

being pumped is sensitive to temperature changes.

.3.1 Pump bearings

A major difference between magnetic drive pumps and the

conventional style is the location and type of bearings. In conventional

pump designs, the beatings are usually located well away from the

pumped liquid in a well controlled environment. In addition, the

operator has a wide choice of appropriate lubricants that can be

utilized. With magnetic drive pumps however, the beatings on the

impeller shaft are lubricated by the pumpage that may not be an

appropriate lubricant. In addition, when the pump runs dry, or operates

at very low flows, the lubricant tends to disappear and the bearing will

overheat. Even if the pump survives that abuse it may still not last very

long if such a condition is followed by a cool liquid entering the pump.

Under these conditions the beatings will be subjected to a thermal

shock which could cause cracking or total destruction.

It is also important to note that, as the beatings are usually of the sleeve

type with slots or grooves to supply the lubricant to the bearing

running surface, any solids in the pumpage will be detrimental to the

bearing reliability. The material of these beatings is usually either Silicon

Carbide or Carbon, and while the Silicon Carbide is a longer wearing

157