Page 175 -

P. 175

The Practical Pumping Handbook ....................

9.2.3 Pump discharge head

The discharge head can be either a

fabricated part of a casting that

provides a base from which the

pump is suspended and on which

the driver is mounted. It also

directs the flow from the vertical

column to a horizontal flanged

discharge nozzle that will be

connected to the system. The

discharge head is fitted with a

stuffing box or seal chamber

through which the line shaft

passes to connect with the driver.

Depending on the application,

either packing or mechanical seals

can be used. When an enclosing

tube is used, a tension nut is fitted

to keep the tube under tension

and to hold it straight.

9.2.4 Vertical pump Figure 9.11. Vertical pump discharge head

performance (Reproduced with permission of Goulds

The performance of the vertical Pumps, ITT Industries)

turbine pumps using the mixed

flow or axial flow impellers can

develop some significant oper-

ational differences, particularly in

the larger sizes.

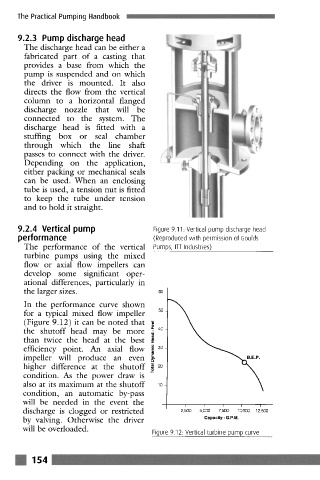

In the performance curve shown

for a typical mixed flow impeller ~0

(Figure 9.12) it can be noted that

the shutoff head may be more ~, 40

than twice the head at the best

u

efficiency point. An axial flow ] 30

g

impeller will produce an even,.,

higher difference at the shutoff ~_ 20

condition. As the power draw is

also at its maximum at the shutoff ~0

condition, an automatic by-pass

will be needed in the event the

I I I I I

discharge is clogged or restricted 2, 500 5, 000 7, 500 1 O, 000 12, 500

by valving. Otherwise the driver Capacity - G.P.M.

will be overloaded. Figure 9.12: Vertical turbine pump curve

m 154 .........