Page 170 -

P. 170

......................... Special Pumps

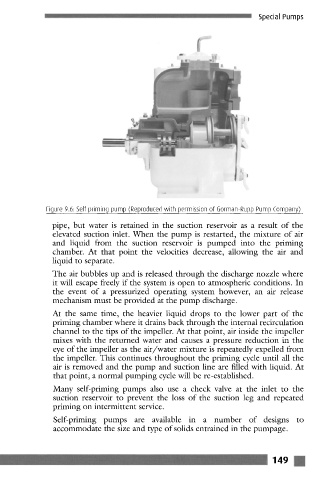

Figure 9.6: Self priming pump (Reproduced with permission of Gorman-Rupp Pump Company)

pipe, but water is retained in the suction reservoir as a result of the

elevated suction inlet. When the pump is restarted, the mixture of air

and liquid from the suction reservoir is pumped into the priming

chamber. At that point the velocities decrease, allowing the air and

liquid to separate.

The air bubbles up and is released through the discharge nozzle where

it will escape freely if the system is open to atmospheric conditions. In

the event of a pressurized operating system however, an air release

mechanism must be provided at the pump discharge.

At the same time, the heavier liquid drops to the lower part of the

priming chamber where it drains back through the internal recirculation

channel to the tips of the impeller. At that point, air inside the impeller

mixes with the returned water and causes a pressure reduction in the

eye of the impeller as the air/water mixture is repeatedly expelled from

the impeller. This continues throughout the priming cycle until all the

air is removed and the pump and suction line are filled with liquid. At

that point, a normal pumping cycle will be re-established.

Many self-priming pumps also use a check valve at the inlet to the

suction reservoir to prevent the loss of the suction leg and repeated

priming on intermittent service.

Self-priming pumps arc available in a number of designs to

accommodate the size and type of solids entrained in the pumpagc.

' .................. - ........... iiiiiiiiiiiiiiiiiiiii_ - i 149