Page 171 -

P. 171

The Practical Pumping Handbook ....................... ~-.:N

9.2 Vertical turbine pumps

Vertical Turbine Pumps have

come a long way since their

humble beginnings in the

irrigation field, and are now used

in a wide variety of applications.

While they are still utilized to raise

water from underground aquifers,

ponds, lakes, rivers and oceans,

they now supply such industries as

Water Treatment Facilities, Pulp

and Paper Mills and Power

Generating Stations. They are also

an integral part of numerous Fire

Protection Systems, as well as

many of the processes in the

Petrochemical Industries.

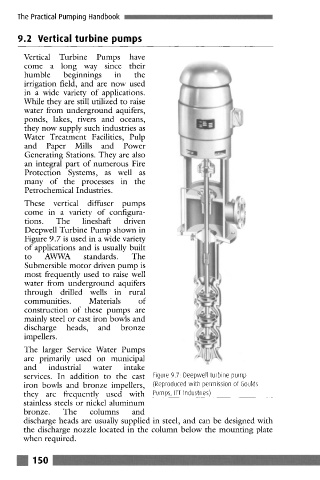

These vertical diffuser pumps

come in a variety of configura-

tions. The lineshaft driven

Deepwell Turbine Pump shown in

Figure 9.7 is used in a wide variety

of applications and is usually built

to AWWA standards. The

Submersible motor driven pump is

most frequently used to raise well

water from underground aquifers

through drilled wells in rural

communities. Materials of

construction of these pumps are

mainly steel or cast iron bowls and

discharge heads, and bronze

impellers.

The larger Service Water Pumps

are primarily used on municipal

and industrial water intake

services. In addition to the cast Figure 9.7: Oeepwell turbine pump

iron bowls and bronze impellers, (Reproduced with permission of G0ulds

they are frequently used with Pumps, ITT Industries)

stainless steels or nickel aluminum

bronze. The columns and

discharge heads are usually supplied in steel, and can be designed with

the discharge nozzle located in the column below the mounting plate

when required.

lm 150 iiiiii; ...... " ..... ------.::; ....... .