Page 167 -

P. 167

The Practical Pumping Handbook ..............................................................

through a connection close to the discharge nozzle of the pump, either

manually or by an automated system. At that point the pump can then

be started without difficulty and will operate under normal conditions.

While priming the pump is always essential on installation and initial

startup, it can also be necessary when the pump is operating on

intermittent duty. Under these conditions the pump will occasionally

stop, thus leaving the liquid in the suction line to the mercy of gravity

that will tend to empty that line. To prevent such an occurrence, a foot

valve is fitted to the bottom of the suction line in the sump. These

valves are usually designed with a flap or ball positioned in such a way

that, the normal flow direction of the liquid will hold the valve open.

However, when the flow through that valve reverses, the flap or ball

will close against the seat, thus holding the liquid in the suction line.

Unfortunately, if a small piece of debris is caught between the seat and

the flap or ball, the valve will stick open and the suction line will drain

out into the sump and the pump loses its prime. For occasional use

where the pump is not an important part of the process, and operators

are readily available, this repetitive priming may be quite acceptable.

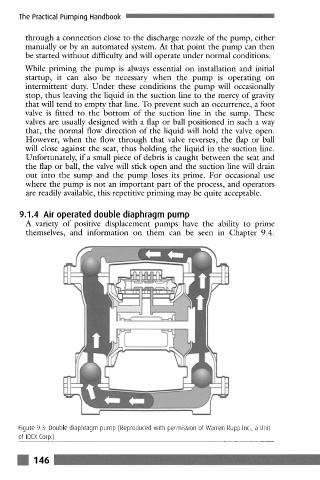

9.1.4 Air operated double diaphragm pump

A variety of positive displacement pumps have the ability to prime

themselves, and information on them can be seen in Chapter 9.4.

Figure 9.3: Double diaphragm pump (Reproduced with permission of Warren Rupp Inc., a Unit

of IDEX Corp.)

m 146