Page 169 -

P. 169

The Practical Pumping Handbook

,",r [

m

I ~riming

Tank

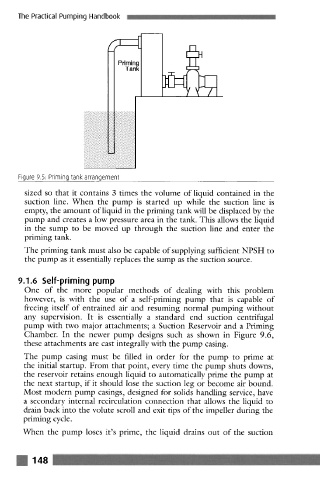

Figure 9.5: Priming tank arrangement

sized so that it contains 3 times the volume of liquid contained in the

suction line. When the pump is started up while the suction line is

empty, the amount of liquid in the priming tank will be displaced by the

pump and creates a low pressure area in the tank. This allows the liquid

in the sump to be moved up through the suction line and enter the

priming tank.

The priming tank must also be capable of supplying sufficient NPSH to

the pump as it essentially replaces the sump as the suction source.

9.1.6 Self-priming pump

One of the more popular methods of dealing with this problem

however, is with the use of a self-priming pump that is capable of

freeing itself of entrained air and resuming normal pumping without

any supervision. It is essentially a standard end suction centrifugal

pump with two major attachments; a Suction Reservoir and a Priming

Chamber. In the newer pump designs such as shown in Figure 9.6,

these attachments are cast integrally with the pump casing.

The pump casing must be filled in order for the pump to prime at

the initial startup. From that point, every time the pump shuts downs,

the reservoir retains enough liquid to automatically prime the pump at

the next startup, if it should lose the suction leg or become air bound.

Most modern pump casings, designed for solids handling service, have

a secondary internal recirculation connection that allows the liquid to

drain back into the volute scroll and exit tips of the impeller during the

priming cycle.

When the pump loses it's prime, the liquid drains out of the suction

148