Page 165 -

P. 165

The Practical Pumping Handbook .............................................

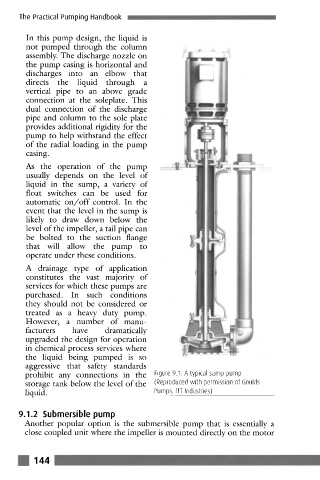

In this pump design, the liquid is

not pumped through the column

assembly. The discharge nozzle on

the pump casing is horizontal and

discharges into an elbow that

directs the liquid through a

vertical pipe to an above grade

connection at the soleplate. This

dual connection of the discharge

pipe and column to the sole plate

provides additional rigidity for the

pump to help withstand the effect

of the radial loading in the pump

casing.

As the operation of the pump

usually depends on the level of

liquid in the sump, a variety of

float switches can be used for

automatic on/off control. In the

event that the level in the sump is

likely to draw down below the

level of the impeller, a tail pipe can

be bolted to the suction flange

that will allow the pump to

operate under these conditions.

A drainage type of application

constitutes the vast majority of

services for which these pumps are

purchased. In such conditions

they should not be considered or

treated as a heavy duty pump.

However, a number of manu-

facturers have dramatically

upgraded the design for operation

in chemical process services where

the liquid being pumped is so

aggressive that safety standards

prohibit any connections in the Figure 9.1. A typical sump pump

storage tank below the level of the (Reproduced with permission of 6oulds

liquid. Pumps, ITT Industries)

9.1.2 Submersible pump

Another popular option is the submersible pump that is essentially a

close coupled unit where the impeller is mounted directly on the motor

! 144