Page 181 -

P. 181

The Practical Pumping Handbook .................... _ ............ '7:: .....

t

--,I,,.

|

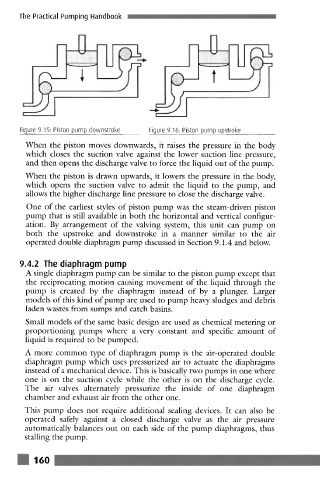

Figure 9.15: Piston pump downstroke Figure 9.16. Piston pump upstroke

When the piston moves downwards, it raises the pressure in the body

which closes the suction valve against the lower suction line pressure,

and then opens the discharge valve to force the liquid out of the pump.

When the piston is drawn upwards, it lowers the pressure in the body,

which opens the suction valve to admit the liquid to the pump, and

allows the higher discharge line pressure to close the discharge valve.

One of the earliest styles of piston pump was the steam-driven piston

pump that is still available in both the horizontal and vertical configur-

ation. By arrangement of the valving system, this unit can pump on

both the upstroke and downstroke in a manner similar to the air

operated double diaphragm pump discussed in Section 9.1.4 and below.

9.4.2 The diaphragm pump

A single diaphragm pump can be similar to the piston pump except that

the reciprocating motion causing movement of the liquid through the

pump is created by the diaphragm instead of by a plunger. Larger

models of this kind of pump are used to pump heavy sludges and debris

laden wastes from sumps and catch basins.

Small models of the same basic design are used as chemical metering or

proportioning pumps where a very constant and specific amount of

liquid is required to be pumped.

A more common type of diaphragm pump is the air-operated double

diaphragm pump which uses pressurized air to actuate the diaphragms

instead of a mechanical device. This is basically two pumps in one where

one is on the suction cycle while the other is on the discharge cycle.

The air valves alternately pressurize the inside of one diaphragm

chamber and exhaust air from the other one.

This pump does not require additional sealing devices. It can also be

operated safely against a closed discharge valve as the air pressure

automatically balances out on each side of the pump diaphragms, thus

stalling the pump.

160