Page 184 -

P. 184

11 111 ........ . . . . . . . . . . . . . . . . . . . . . . Special Pumps

The successive sets of seals form fully enclosed cavities which move

continuously from inlet to outlet. These cavities trap liquid at the inlet

and carry it along to the outlet in a smooth flow.

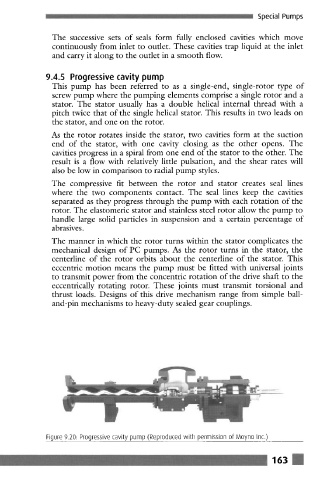

.4.5 Progressive cavity pump

This pump has been referred to as a single-end, single-rotor type of

screw pump where the pumping elements comprise a single rotor and a

stator. The stator usually has a double helical internal thread with a

pitch twice that of the single helical stator. This results in two leads on

the stator, and one on the rotor.

As the rotor rotates inside the stator, two cavities form at the suction

end of the stator, with one cavity closing as the other opens. The

cavities progress in a spiral from one end of the stator to the other. The

result is a flow with relatively little pulsation, and the shear rates will

also be low in comparison to radial pump styles.

The compressive fit between the rotor and stator creates seal lines

where the two components contact. The seal lines keep the cavities

separated as they progress through the pump with each rotation of the

rotor. The elastomeric stator and stainless steel rotor allow the pump to

handle large solid particles in suspension and a certain percentage of

abrasives.

The manner in which the rotor turns within the stator complicates the

mechanical design of PC pumps. As the rotor turns in the stator, the

centerline of the rotor orbits about the centerline of the stator. This

eccentric motion means the pump must be fitted with universal joints

to transmit power from the concentric rotation of the drive shaft to the

eccentrically rotating rotor. These joints must transmit torsional and

thrust loads. Designs of this drive mechanism range from simple ball-

and-pin mechanisms to heavy-duty sealed gear couplings.

Figure 9.20: Progressive cavity pump (Reproduced with permission of Moyno Inc.)

163 I