Page 32 -

P. 32

.................................... Centrifugal Pumps

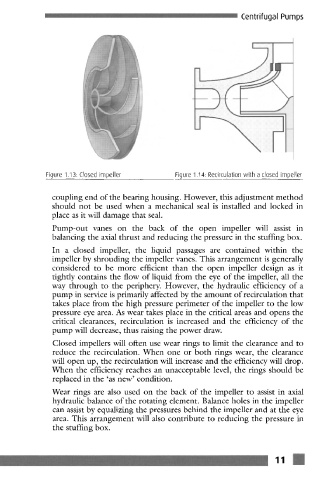

Figure 1.13: Closed impeller Figure 1.14: Recirculation with a closed impeller

coupling end of the bearing housing. However, this adjustment method

should not be used when a mechanical seal is installed and locked in

place as it will damage that seal.

Pump-out vanes on the back of the open impeller will assist in

balancing the axial thrust and reducing the pressure in the stuffing box.

In a closed impeller, the liquid passages are contained within the

impeller by shrouding the impeller vanes. This arrangement is generally

considered to be more efficient than the open impeller design as it

tightly contains the flow of liquid from the eye of the impeller, all the

way through to the periphery. However, the hydraulic efficiency of a

pump in service is primarily affected by the amount of recirculation that

takes place from the high pressure perimeter of the impeller to the low

pressure eye area. As wear takes place in the critical areas and opens the

critical clearances, recirculation is increased and the efficiency of the

pump will decrease, thus raising the power draw.

Closed impellers will often use wear rings to limit the clearance and to

reduce the recirculation. When one or both tings wear, the clearance

will open up, the recirculation will increase and the efficiency will drop.

When the efficiency reaches an unacceptable level, the rings should be

replaced in the 'as new' condition.

Wear tings are also used on the back of the impeller to assist in axial

hydraulic balance of the rotating clement. Balance holes in the impeller

can assist by equalizing the pressures behind the impeller and at the eye

area. This arrangement will also contribute to reducing the pressure in

the stuffing box.

~_ 11 ~