Page 47 - The Six Sigma Project Planner

P. 47

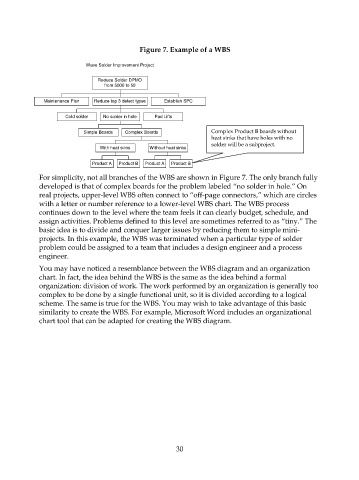

Figure 7. Example of a WBS

Wave Solder Improvement Project

Reduce Solder DPMO

from 5000 to 50

Maintenance Plan Reduce top 3 defect types Establish SPC

Cold solder No solder in hole Pad Lifts

Simple Boards Complex Boards Complex Product B boards without

heat sinks that have holes with no

solder will be a subproject.

With heat sinks Without heat sinks

Product A Product B Product A Product B

For simplicity, not all branches of the WBS are shown in Figure 7. The only branch fully

developed is that of complex boards for the problem labeled “no solder in hole.” On

real projects, upper-level WBS often connect to “off-page connectors,” which are circles

with a letter or number reference to a lower-level WBS chart. The WBS process

continues down to the level where the team feels it can clearly budget, schedule, and

assign activities. Problems defined to this level are sometimes referred to as “tiny.” The

basic idea is to divide and conquer larger issues by reducing them to simple mini-

projects. In this example, the WBS was terminated when a particular type of solder

problem could be assigned to a team that includes a design engineer and a process

engineer.

You may have noticed a resemblance between the WBS diagram and an organization

chart. In fact, the idea behind the WBS is the same as the idea behind a formal

organization: division of work. The work performed by an organization is generally too

complex to be done by a single functional unit, so it is divided according to a logical

scheme. The same is true for the WBS. You may wish to take advantage of this basic

similarity to create the WBS. For example, Microsoft Word includes an organizational

chart tool that can be adapted for creating the WBS diagram.

30