Page 138 - The Toyota Way Fieldbook

P. 138

Chapter 6. Establish Standardized Processes and Procedures 115

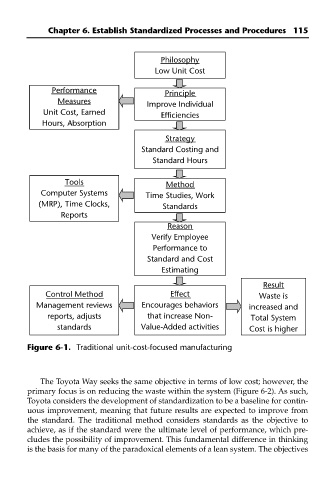

Philosophy

Low Unit Cost

Performance Principle

Measures Improve Individual

Unit Cost, Earned Efficiencies

Hours, Absorption

Strategy

Standard Costing and

Standard Hours

Tools Method

Computer Systems Time Studies, Work

(MRP), Time Clocks, Standards

Reports

Reason

Verify Employee

Performance to

Standard and Cost

Estimating

Result

Control Method Effect Waste is

Management reviews Encourages behaviors increased and

reports, adjusts that increase Non- Total System

standards Value-Added activities Cost is higher

Figure 6-1. Traditional unit-cost-focused manufacturing

The Toyota Way seeks the same objective in terms of low cost; however, the

primary focus is on reducing the waste within the system (Figure 6-2). As such,

Toyota considers the development of standardization to be a baseline for contin-

uous improvement, meaning that future results are expected to improve from

the standard. The traditional method considers standards as the objective to

achieve, as if the standard were the ultimate level of performance, which pre-

cludes the possibility of improvement. This fundamental difference in thinking

is the basis for many of the paradoxical elements of a lean system. The objectives