Page 142 - The Toyota Way Fieldbook

P. 142

Chapter 6. Establish Standardized Processes and Procedures 119

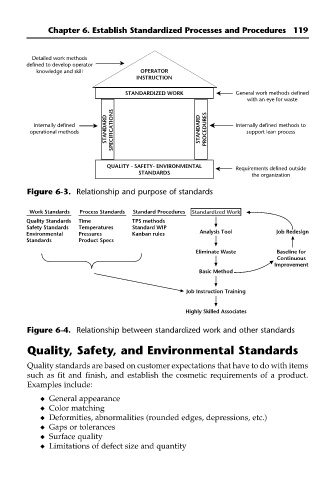

Detailed work methods

defined to develop operator

knowledge and skill OPERATOR

INSTRUCTION

STANDARDIZED WORK General work methods defined

with an eye for waste

STANDARD SPECIFICATIONS STANDARD PROCEDURES

Internally defined Internally defined methods to

operational methods support lean process

QUALITY - SAFETY- ENVIRONMENTAL

Requirements defined outside

STANDARDS

the organization

Figure 6-3. Relationship and purpose of standards

Work Standards Process Standards Standard Procedures Standardized Work

Quality Standards Time TPS methods

Safety Standards Temperatures Standard WIP

Environmental Pressures Kanban rules Analysis Tool Job Redesign

Standards Product Specs

Eliminate Waste Baseline for

Continuous

Improvement

Basic Method

Job Instruction Training

Highly Skilled Associates

Figure 6-4. Relationship between standardized work and other standards

Quality, Safety, and Environmental Standards

Quality standards are based on customer expectations that have to do with items

such as fit and finish, and establish the cosmetic requirements of a product.

Examples include:

◆ General appearance

◆ Color matching

◆ Deformities, abnormalities (rounded edges, depressions, etc.)

◆ Gaps or tolerances

◆ Surface quality

◆ Limitations of defect size and quantity