Page 139 - The Toyota Way Fieldbook

P. 139

116 THE TOYOTA WAY FIELDBOOK

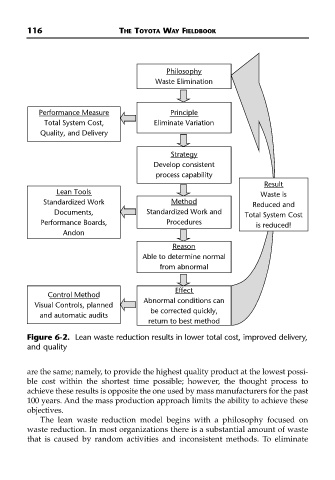

Philosophy

Waste Elimination

Performance Measure Principle

Total System Cost, Eliminate Variation

Quality, and Delivery

Strategy

Develop consistent

process capability

Result

Lean Tools Waste is

Standardized Work Method Reduced and

Documents, Standardized Work and Total System Cost

Performance Boards, Procedures is reduced!

Andon

Reason

Able to determine normal

from abnormal

Effect

Control Method

Abnormal conditions can

Visual Controls, planned

be corrected quickly,

and automatic audits

return to best method

Figure 6-2. Lean waste reduction results in lower total cost, improved delivery,

and quality

are the same; namely, to provide the highest quality product at the lowest possi-

ble cost within the shortest time possible; however, the thought process to

achieve these results is opposite the one used by mass manufacturers for the past

100 years. And the mass production approach limits the ability to achieve these

objectives.

The lean waste reduction model begins with a philosophy focused on

waste reduction. In most organizations there is a substantial amount of waste

that is caused by random activities and inconsistent methods. To eliminate