Page 161 - The Toyota Way Fieldbook

P. 161

138 THE TOYOTA WAY FIELDBOOK

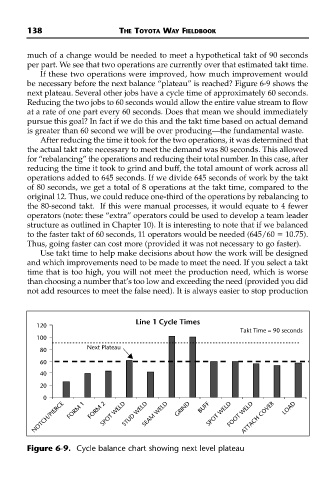

much of a change would be needed to meet a hypothetical takt of 90 seconds

per part. We see that two operations are currently over that estimated takt time.

If these two operations were improved, how much improvement would

be necessary before the next balance “plateau” is reached? Figure 6-9 shows the

next plateau. Several other jobs have a cycle time of approximately 60 seconds.

Reducing the two jobs to 60 seconds would allow the entire value stream to flow

at a rate of one part every 60 seconds. Does that mean we should immediately

pursue this goal? In fact if we do this and the takt time based on actual demand

is greater than 60 second we will be over producing—the fundamental waste.

After reducing the time it took for the two operations, it was determined that

the actual takt rate necessary to meet the demand was 80 seconds. This allowed

for “rebalancing” the operations and reducing their total number. In this case, after

reducing the time it took to grind and buff, the total amount of work across all

operations added to 645 seconds. If we divide 645 seconds of work by the takt

of 80 seconds, we get a total of 8 operations at the takt time, compared to the

original 12. Thus, we could reduce one-third of the operations by rebalancing to

the 80-second takt. If this were manual processes, it would equate to 4 fewer

operators (note: these “extra” operators could be used to develop a team leader

structure as outlined in Chapter 10). It is interesting to note that if we balanced

to the faster takt of 60 seconds, 11 operators would be needed (645/60 10.75).

Thus, going faster can cost more (provided it was not necessary to go faster).

Use takt time to help make decisions about how the work will be designed

and which improvements need to be made to meet the need. If you select a takt

time that is too high, you will not meet the production need, which is worse

than choosing a number that’s too low and exceeding the need (provided you did

not add resources to meet the false need). It is always easier to stop production

Line 1 Cycle Times

120

Takt Time = 90 seconds

100

Next Plateau

80

60

40

20

0 BUFF

ATTACH COVER

NOTCH/PIERCE FORM 1 FORM 2 SPOT WELD STUD WELD SEAM WELD GRIND SPOT WELD FOOT WELD LOAD

Figure 6-9. Cycle balance chart showing next level plateau