Page 162 - The Toyota Way Fieldbook

P. 162

Chapter 6. Establish Standardized Processes and Procedures 139

when the output is too high than it is to get more out if it’s too low. When in

doubt, choose a higher demand and a lower takt time.

Importance of Visual Controls

The use of visual controls is the most important step in the process of develop-

ing standardization. Unfortunately, it is also the aspect of a lean process that is

most often belittled. We frequently hear, “They are just doing 5S.” Perhaps this

is due to the examples of visual control most often cited, namely, markings on

the floor to indicate the location of trash containers and other items in the work

area, which are viewed as “silly” and perhaps insulting to the intelligence of

employees. Another example is signs that are used to identify the proper location

of items or the type of material stored in a location. Managers and employees

often respond with, “We all know what belongs there.” However, when asked

to identify specific conditions such as the standard quantity, the minimum or

maximum, or the supplying operation, the response is usually less certain.

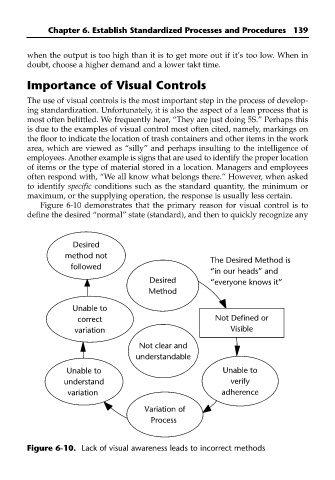

Figure 6-10 demonstrates that the primary reason for visual control is to

define the desired “normal” state (standard), and then to quickly recognize any

Desired

method not

The Desired Method is

followed

“in our heads” and

Desired “everyone knows it”

Method

Unable to

correct Not Defined or

variation Visible

Not clear and

understandable

Unable to Unable to

understand verify

variation adherence

Variation of

Process

Figure 6-10. Lack of visual awareness leads to incorrect methods