Page 376 - The Toyota Way Fieldbook

P. 376

350 THE TOYOTA WAY FIELDBOOK

Production Losses by Category

80 75

70

60

60

Minutes per Shift 50

40

30

20

20

10

0

Cycle Run Time Scrap

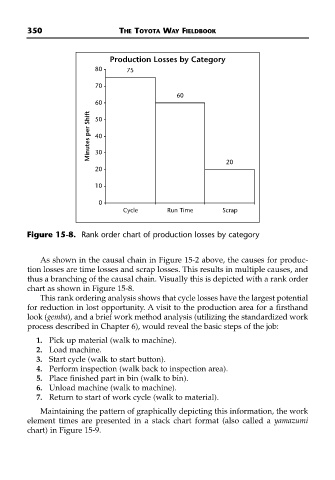

Figure 15-8. Rank order chart of production losses by category

As shown in the causal chain in Figure 15-2 above, the causes for produc-

tion losses are time losses and scrap losses. This results in multiple causes, and

thus a branching of the causal chain. Visually this is depicted with a rank order

chart as shown in Figure 15-8.

This rank ordering analysis shows that cycle losses have the largest potential

for reduction in lost opportunity. A visit to the production area for a firsthand

look (gemba), and a brief work method analysis (utilizing the standardized work

process described in Chapter 6), would reveal the basic steps of the job:

1. Pick up material (walk to machine).

2. Load machine.

3. Start cycle (walk to start button).

4. Perform inspection (walk back to inspection area).

5. Place finished part in bin (walk to bin).

6. Unload machine (walk to machine).

7. Return to start of work cycle (walk to material).

Maintaining the pattern of graphically depicting this information, the work

element times are presented in a stack chart format (also called a yamazumi

chart) in Figure 15-9.