Page 435 - The Toyota Way Fieldbook

P. 435

408 THE TOYOTA WAY FIELDBOOK

the machine goes down the next process keeps working off of inventory anyway?

When machine shutdowns choke the next process so it also shuts down, there is a

sense of urgency to fix the machine and do your preventive maintenance.

Also, the tools are there to support waste elimination, not as stand-alone

tools. Take reducing changeover times, the main benefit of which is that you can

change over more often, reduce batch size, and support leveled production. But

as a stand-alone tool, we’ve seen many companies use changeover reduction to

simply produce more parts and make even larger batches. This clearly sends the

wrong message.

Company X Production System Approach

Now let’s jump way up to the total organization level. Let’s say the vice president

of manufacturing decides to get serious about lean. Through reading, benchmark-

ing visits, or a few successful kaizen events or hot projects, this executive proclaims,

“We need a true lean production system.” This is a noble vision and ultimately

something we want with lean.

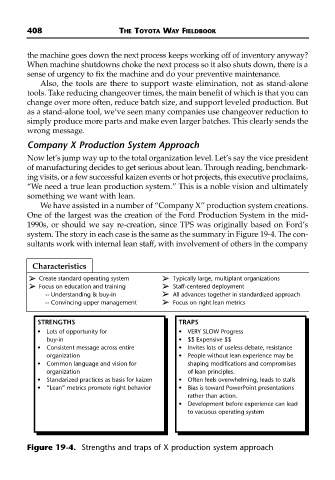

We have assisted in a number of “Company X” production system creations.

One of the largest was the creation of the Ford Production System in the mid-

1990s, or should we say re-creation, since TPS was originally based on Ford’s

system. The story in each case is the same as the summary in Figure 19-4. The con-

sultants work with internal lean staff, with involvement of others in the company

Characteristics

Create standard operating system Typically large, multiplant organizations

Focus on education and training Staff-centered deployment

-- Understanding & buy-in All advances together in standardized approach

-- Convincing upper management Focus on right lean metrics

STRENGTHS TRAPS

• Lots of opportunity for • VERY SLOW Progress

buy-in • $$ Expensive $$

• Consistent message across entire • Invites lots of useless debate, resistance

organization • People without lean experience may be

• Common language and vision for shaping modifications and compromises

organization of lean principles.

• Standarized practices as basis for kaizen • Often feels overwhelming, leads to stalls

• “Lean” metrics promote right behavior • Bias is toward PowerPoint presentations

rather than action.

• Development before experience can lead

to vacuous operating system

Figure 19-4. Strengths and traps of X production system approach