Page 451 - The Toyota Way Fieldbook

P. 451

Chapter 19. Lean Implementation Strategies and Tactics 421

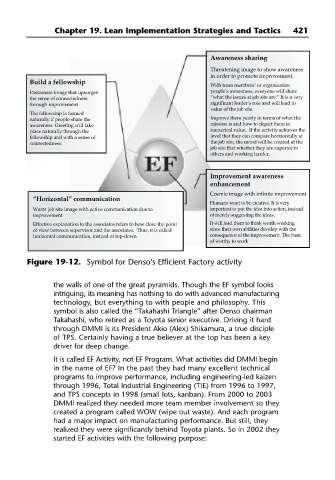

Awareness sharing

Threatening image to show awareness

in order to promote improvement.

Build a fellowship

With team members’ or organization

Passionate image that upsurges people’s awareness, everyone will share

the sense of connectedness “what the issues at job site are.” It is a very

through improvement significant leader’s role and will lead to

value of the job site.

The fellowship is formed

naturally if people share the Improve them yearly in terms of what the

awareness. Greeting will take mission is and how to depict them in

place naturally through the numerical value. If the activity achieves the

fellowship and with a sense of level that they can compare horizontally at

connectedness. the job site, the mood will be created at the

job site that whether they are superior to

others and working harder.

Improvement awareness

enhancement

Cosmic image with infinite improvement

“Horizontal” communication

Humans want to be creative. It is very

Warm job site image with active communication due to important to put the idea into action, instead

improvement of merely suggesting the ideas.

Effective explanation to the associates refers to how close the point It will lead them to think worth working

of view between supervisor and the associates. Thus, it is called since their own abilities develop with the

horizontal communication, instead of top-down consequence of the improvement. The basic

of worthy to work

Figure 19-12. Symbol for Denso’s Efficient Factory activity

the walls of one of the great pyramids. Though the EF symbol looks

intriguing, its meaning has nothing to do with advanced manufacturing

technology, but everything to with people and philosophy. This

symbol is also called the “Takahashi Triangle” after Denso chairman

Takahashi, who retired as a Toyota senior executive. Driving it hard

through DMMI is its President Akio (Alex) Shikamura, a true disciple

of TPS. Certainly having a true believer at the top has been a key

driver for deep change.

It is called EF Activity, not EF Program. What activities did DMMI begin

in the name of EF? In the past they had many excellent technical

programs to improve performance, including engineering-led kaizen

through 1996, Total Industrial Engineering (TIE) from 1996 to 1997,

and TPS concepts in 1998 (small lots, kanban). From 2000 to 2003

DMMI realized they needed more team member involvement so they

created a program called WOW (wipe out waste). And each program

had a major impact on manufacturing performance. But still, they

realized they were significantly behind Toyota plants. So in 2002 they

started EF activities with the following purpose: