Page 447 - The Toyota Way Fieldbook

P. 447

Chapter 19. Lean Implementation Strategies and Tactics 417

S-Secondary

P-Primary Metric (s) Original Target Cell 1 Month 6 Months 9 Months

State of

Later

Later

Later

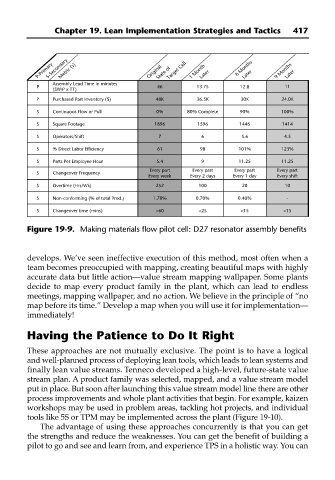

P Assembly Lead Time in minutes 46 13.75 12.8 11

(SWIP x TT)

P Purchased Part Inventory ($) 48K 36.5K 30K 24.0K

S Continuous Flow or Pull 0% 80% Complete 90% 100%

S Square Footage 1896 1596 1446 1414

S Operators/Shift 7 6 5.6 4.5

S % Direct Labor Efficiency 61 98 101% 123%

S Parts Per Employee Hour 5.4 9 11.25 11.25

Every part Every part Every part Every part

S Changeover Frequency

Every week Every 2 days Every 1 day Every shift

S Overtime (Hrs/Wk) 252 100 20 10

S Non-conforming (% of total Prod.) 1.70% 0.70% 0.40% -

S Changeover time (mins) >60 <25 <15 <15

Figure 19-9. Making materials flow pilot cell: D27 resonator assembly benefits

develops. We’ve seen ineffective execution of this method, most often when a

team becomes preoccupied with mapping, creating beautiful maps with highly

accurate data but little action—value stream mapping wallpaper. Some plants

decide to map every product family in the plant, which can lead to endless

meetings, mapping wallpaper, and no action. We believe in the principle of “no

map before its time.” Develop a map when you will use it for implementation—

immediately!

Having the Patience to Do It Right

These approaches are not mutually exclusive. The point is to have a logical

and well-planned process of deploying lean tools, which leads to lean systems and

finally lean value streams. Tenneco developed a high-level, future-state value

stream plan. A product family was selected, mapped, and a value stream model

put in place. But soon after launching this value stream model line there are other

process improvements and whole plant activities that begin. For example, kaizen

workshops may be used in problem areas, tackling hot projects, and individual

tools like 5S or TPM may be implemented across the plant (Figure 19-10).

The advantage of using these approaches concurrently is that you can get

the strengths and reduce the weaknesses. You can get the benefit of building a

pilot to go and see and learn from, and experience TPS in a holistic way. You can