Page 443 - The Toyota Way Fieldbook

P. 443

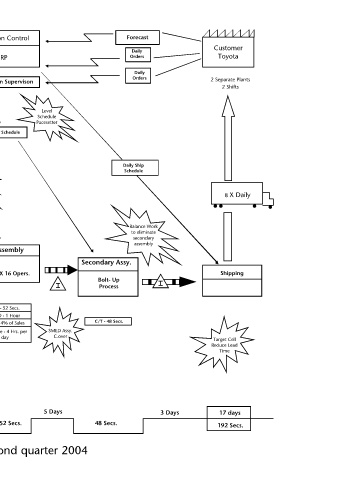

Customer Toyota 2 Separate Plants 2 Shifts 8 X Daily Shipping Target Cell Reduce Lead Time 17 days 192 Secs.

3 Days

Forecast Daily Orders Daily Orders Daily Ship Schedule Balance Work to eliminate secondary assembly

Secondary Assy. Bolt- Up Process C/T - 48 Secs. 48 Secs.

SMED Assy. C.over

Level Schedule Pacesetter 5 Days

Production Control MRP Production Supervison Weekly Schedule Assembly X 16 Opers. C/T - 52 Secs. C/O - 1 Hour Scrap - 4% of Sales Overtime - 4 Hrs. per day 52 Secs.

Lean Bascis -EPEI -Line Balance -S/W -Layout Scrap - Six Sigma Toyota 500N center cell current state second quarter 2004

4 Days 5 Days 4 Days 1.5 Days 5 days

Forecast Add press to F/B delivery route Implement timed Material deliveries Create container Kanban

2.5 X / Week Weekly Schedule

Tube Bending Process C/T - 30 Secs. C/O - 15 Mins. Press Process C/T - 2 Secs. C/O - 1 Hour Purchase Outside Sources Spun Res. Process C/T - 62 Secs. C/O - 0 94 Secs

Suppliers Purchase, Steel. Pipe 5 X Week Pipe 2 Days Steel 2 Days Introduce Weekly Kanban Purchase 4 Days Supplier Pull 4 Days 4 days Figure 19-7.