Page 88 - The Toyota Way Fieldbook

P. 88

Chapter 4. Create Initial Process Stability 65

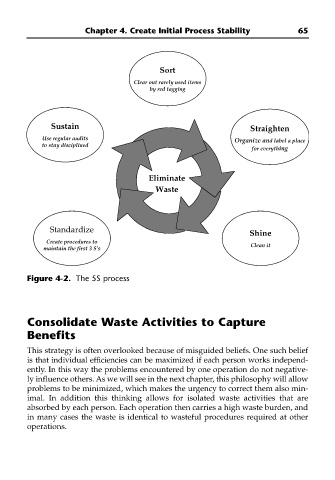

Sort

Clear out rarely used items

by red tagging

Sustain Straighten

Use regular audits Organize and label a place

to stay disciplined

for everything

Eliminate

Waste

Standardize

Shine

Create procedures to

Clean it

maintain the first 3 S’s

Figure 4-2. The 5S process

Consolidate Waste Activities to Capture

Benefits

This strategy is often overlooked because of misguided beliefs. One such belief

is that individual efficiencies can be maximized if each person works independ-

ently. In this way the problems encountered by one operation do not negative-

ly influence others. As we will see in the next chapter, this philosophy will allow

problems to be minimized, which makes the urgency to correct them also min-

imal. In addition this thinking allows for isolated waste activities that are

absorbed by each person. Each operation then carries a high waste burden, and

in many cases the waste is identical to wasteful procedures required at other

operations.